Canon iR5055 Series Service Manual

Hide thumbs

Also See for iR5055 Series:

- User manual (98 pages) ,

- Easy operation manual (60 pages) ,

- Service manual (596 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Summary of Contents for Canon iR5055 Series

- Page 1 Service Manual iR5075/5065/5055 Series Feb 29 2008...

- Page 3 Canon will release technical information as the need arises. In the event of major changes in the contents of this manual over a long or short period, Canon will issue a new edition of this manual.

- Page 4 Introduction Symbols Used This documentation uses the following symbols to indicate special information: Symbol Description Indicates an item of a non-specific nature, possibly classified as Note, Caution, or Warning. Indicates an item requiring care to avoid electric shocks. Indicates an item requiring care to avoid combustion (fire). Indicates an item prohibiting disassembly to avoid electric shocks or problems.

- Page 5 Introduction The following rules apply throughout this Service Manual: 1. Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical and mechanical systems with refer- ence to the timing of operation. In the diagrams, represents the path of mechanical drive; where a signal name accompanies the symbol , the arrow indicates the direction of the electric signal.

-

Page 7: Table Of Contents

Contents Contents Chapter 1 Introduction 1.1 System Construction ..........................1- 1 1.1.1 System Configuration with Pickup/Delivery Accessories (230V)EUR ..............1- 1 1.1.2 System Configuration with Printing/Transmission Accessories (230V)EUR ............1- 1 1.1.3 Functions and Printing/Transmission Accessories (230V) ..................1- 2 1.2 Product Specifications ..........................1- 3 1.2.1 Names of Parts................................ - Page 8 Contents 2.2.7 Installation of Pickup Assembly ..........................2- 10 2.2.8 Attaching Deck Pressure Plate ..........................2- 11 2.2.9 Setting Toner Container ............................2- 11 2.2.10 Connecting the Cable............................2- 12 2.2.11 Checking the Environment Switch ........................2- 12 2.2.12 Attaching the Label ..............................2- 13 2.2.13 Connecting the Power Cord ..........................2- 13 2.2.14 Turning On the Main Power Switch........................2- 14 2.2.15 Toner Stirring ...............................2- 14 2.2.16 Media Cassette Settings ............................2- 14...

- Page 9 Contents 2.12.1 Checking the Parts to Install ..........................2- 31 2.12.2 Turning Off the Host Machine..........................2- 32 2.13 Installing the Voice Guidance Kit ......................2- 32 2.13.1 A point to keep in mind at installation ........................2- 32 2.13.2 Checking the Contents ............................2- 32 2.13.3 Power off of the host machine ..........................

- Page 10 Contents 4.7.2 Main Controller PCB ..............................4- 13 4.7.2.1 Before Removing the Main Controller PCB ........................... 4- 13 4.7.2.2 Removing the Main Controller PCB ............................4- 13 4.7.2.3 When Replacing the Main Controller PCB..........................4- 14 4.7.3 SDRAM ..................................4- 14 4.7.3.1 Before Removing the SDRAM ............................... 4- 14 4.7.3.2 Removing the SDRAM................................

- Page 11 Contents 5.4.1.1 Before Removing the CCD Unit ............................. 5- 17 5.4.1.2 Removing the CCD Unit................................. 5- 17 5.4.1.3 When Replacing the CCD Unit .............................. 5- 17 5.4.2 Copyboard glass..............................5- 18 5.4.2.1 Removing the Copyboard Glass ............................5- 18 5.4.2.2 When Replacing the Copyboard Glass..........................5- 18 5.4.3 Scanning Lamp..............................

- Page 12 Contents 6.3.1.1 Generating the Sync Signal ..............................6- 2 6.3.1.2 Flow of the Sync Signal ................................6- 2 6.3.2 Controlling the Intensity of Laser Light........................6- 2 6.3.2.1 Controlling the Laser Intensity ..............................6- 2 6.3.2.2 APC Control ..................................... 6- 3 6.3.3 Controlling the Laser Scanner Motor ........................6- 4 6.3.3.1 Controlling the Laser Scanner Motor ............................

- Page 13 Contents 7.8.1.4 Others ....................................7- 17 7.9 Separation Mechanism ..........................7- 18 7.9.1 Separation Charging Mechanism .......................... 7- 18 7.9.1.1 Overview ....................................7- 18 7.9.1.2 Correcting the Output to Suit the Environment and the Drum Surface Potential ..............7- 18 7.9.1.3 Others ....................................7- 19 7.10 Parts Replacement Procedure........................7- 20 7.10.1 Process Unit ................................

- Page 14 Contents 7.10.16 Developing Blade ...............................7- 29 7.10.16.1 Before Removing Developing Blade ..........................7- 29 7.10.16.2 Removing Developing Blade ............................. 7- 29 7.10.16.3 Mounting Developing Blade ............................... 7- 29 7.10.17 Transfer/Separation Charging Assembly ......................7- 30 7.10.17.1 Removing Transfer/Separation Charging Assembly ......................7- 30 7.10.17.2 Mounting Transfer/Separation Charging Assembly ......................

- Page 15 Contents 8.6.5 Paper Level Detection Operation (right/left deck)....................8- 21 8.6.6 Identifying the Size of Paper (right/left deck)......................8- 21 8.7 Registration Unit ............................8- 21 8.7.1 Outline ................................... 8- 21 8.7.2 Control System ..............................8- 22 8.8 Duplex Feeding Unit ..........................8- 22 8.8.1 Moving the Paper to the Reversing Assembly After Printing on the 1st Side............

- Page 16 Contents 8.11.14.1 Before Removing the Manual Feeding Pickup Roller......................8- 37 8.11.14.2 Removing the Manual Feeding Pickup Roller ........................8- 37 8.11.15 Manual Feed Roller ............................8- 38 8.11.15.1 Before Removing the Manual Feeding Roller ........................8- 38 8.11.15.2 Removing the Manual Feeding Roller ..........................8- 38 8.11.16 Manual Separation Roller...........................8- 38 8.11.16.1 Before Removing the Manual Separation Roller ........................

- Page 17 Contents 8.11.32.4 Removing the Reversing Sensor 2............................. 8- 47 8.11.33 Reversing Unit ..............................8- 47 8.11.33.1 Before Removing the Reversing Flapper Solenoid ......................8- 47 8.11.33.2 Removing the Reversing Flapper Solenoid........................8- 47 8.11.33.3 Mounting the Reversing Flapper Solenoid ......................... 8- 47 8.11.34 Feeding Belt...............................

- Page 18 Contents 9.3.3 Detecting the Passage of Paper ..........................9- 16 9.3.3.1 Preventing Wrapping of Paper............................... 9- 16 9.4 Protective Functions ..........................9- 17 9.4.1 Detecting an Error Using the Thermistor .......................9- 17 9.4.2 Detecting an Error Using the Thermal Switch......................9- 17 9.4.3 Errors ..................................9- 17 9.5 Parts Replacement Procedure .........................

- Page 19 Contents 9.5.15.1 Before Removing the Internal Delivery Sensor ........................9- 34 9.5.15.2 Removing the Internal Delivery Sensor..........................9- 34 9.5.16 Fixing Inlet Sensor ............................... 9- 34 9.5.16.1 Before Removing the Fixing Inlet Sensor..........................9- 34 9.5.16.2 Removing the Fixing Inlet Sensor ............................9- 34 9.5.16.3 Adjusting the Fixing Inlet Guide ............................

- Page 20 Contents 10.4.5.1 Overview ....................................10- 8 10.4.5.2 SNMP setup ..................................10- 9 10.5 Parts Replacement Procedure ......................10- 12 10.5.1 External Covers..............................10- 12 10.5.1.1 Right Cover (Lower Rear) ..............................10- 12 10.5.1.2 Right Cover (Upper Rear) ..............................10- 12 10.5.1.3 Right Cover (Upper) ................................10- 12 10.5.1.4 Left Cover (Upper) ................................

- Page 21 Contents 10.5.14.2 Removing Accessories Power Supply PCB ........................10- 25 10.5.15 Fixing Heater Power Supply PCB ........................10- 25 10.5.15.1 Before Removing Fixing Heater Power Supply PCB ....................... 10- 25 10.5.15.2 Removing Fixing Heater Power Supply PCB ........................10- 25 10.5.16 Anti-Rush Current PCB............................

- Page 22 Contents Chapter 11 MEAP 11.1 MEAP ..............................11- 1 11.1.1 Checking the Operating Environment........................11- 1 11.1.2 Setting Up the Network ............................11- 4 11.1.3 Setting the method to login to SMS........................11- 5 11.1.4 Login to SMS................................11- 9 11.1.5 Checking Application List ...........................11- 11 11.1.6 Starting and Stopping a MEAP Application......................11- 12 11.1.7 Checking the Platform Information........................11- 13 11.1.8 MEAP Specifications............................11- 14...

- Page 23 Contents 13.2.2 Reader unit ................................13- 2 13.2.3 Printer Unit................................13- 2 13.3 Scheduled Servicing Basic Procedure....................13- 2 13.3.1 Scheduled Servicing Basic Procedure......................... 13- 2 13.3.2 Periodical Servicing Chart Reader Unit ....................... 13- 3 13.3.3 Periodical Servicing Chart Printer Unit ........................ 13- 4 13.3.4 Points to Note for Periodical Servicing ........................

- Page 24 Contents 14.6.6 Adjusting the Position of the Fixing Inlet Guide....................14- 23 14.7 Electrical Components.......................... 14- 23 14.7.1 When Replacing DC Controller PCB .........................14- 23 14.7.2 When Replacing HVT PCB ..........................14- 24 14.7.3 After Replacing the HDD............................14- 24 14.7.4 When Replacing the Main Controller PCB ......................14- 24 14.8 Pickup/Feeding System ........................

- Page 25 Contents 16.1 Error Code Table ............................16- 1 16.1.1 Error Code ................................16- 1 16.2 Error Code Details ..........................16- 2 16.2.1 Detail Error Code ..............................16- 2 16.2.2 E602 in Detail ..............................16- 16 16.3 Error Code (SEND) ..........................16- 18 16.3.1 Results of Self-Diagnosis........................... 16- 18 16.3.2 Error Codes ...............................

- Page 26 Contents 17.6.4 BOARD ................................17- 62 17.6.4.1 BOARD List..................................17- 62 17.7 TEST (Test Print Mode)........................17- 63 17.7.1 COPIER ................................17- 63 17.7.1.1 COPIER List..................................17- 63 17.8 COUNTER (Counter Mode)........................17- 64 17.8.1 COPIER ................................17- 64 17.8.1.1 COPIER List..................................17- 64 Chapter 18 Upgrading 18.1 Outline ..............................

- Page 27 Contents 19.1.2 List of Solvents/Oils ............................. 19- 2...

- Page 28 Contents...

-

Page 29: Chapter 1 Introduction

Chapter 1 Introduction... - Page 31 Contents Contents 1.1 System Construction ..............................1-1 1.1.1 System Configuration with Pickup/Delivery Accessories (230V)EUR ..................1-1 1.1.2 System Configuration with Printing/Transmission Accessories (230V)EUR ................1-1 1.1.3 Functions and Printing/Transmission Accessories (230V)......................1-2 1.2 Product Specifications..............................1-3 1.2.1 Names of Parts ..................................... 1-3 1.2.1.1 External view ........................................1-3 1.2.1.2 Cross-Section ........................................1-5 1.2.2 Using the Machine ..................................

-

Page 33: System Construction

Chapter 1 1.1 System Construction 1.1.1 System Configuration with Pickup/Delivery Accessories (230V)EUR 0015-9473 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N The following shows a typical system configuration: [14] [11] [10] [13] [12] F-1-1 T-1-1 Finisher-AD1 Saddle Finisher-AD2 Shift Tray-D1 Copy Tray-L1... -

Page 34: Functions And Printing/Transmission Accessories (230V)

AMS KIT (license certificate) [18] Universal Send Trial Kit-C1 (license certificate) (standard) [19] Canon Universal Send Kit-F1 (license certificate) 1.1.3 Functions and Printing/Transmission Accessories (230V) 0015-4296 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N The following shows the accessories needed for individual functions:... -

Page 35: Product Specifications

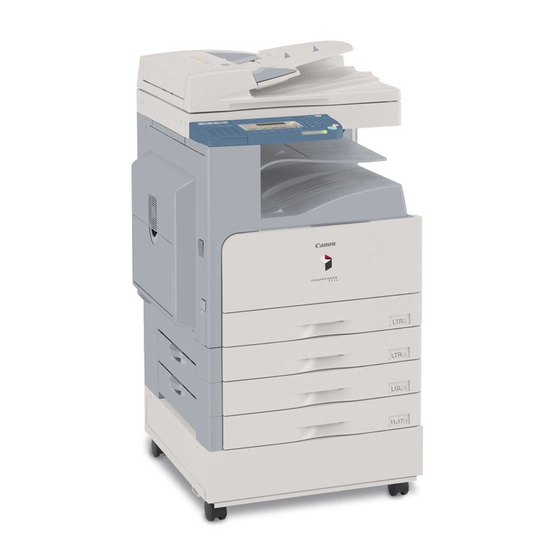

Chapter 1 Function Accessory needed faxing Super G3 Fax Board-Z1 LIPS V Expansion Kit-R1 LIPS printing + transmission SEND Expansion Kit-Q1 LIPS V Expansion Kit-R1 LIPS printing + faxing (1-line) Super G3 Fax Board-Z1 MEAP function - no need for memory expansion (w/ copy boot ROM) both MEAP authentication and MEAP application operation possible - if only MEAP authentication is desired... - Page 36 Chapter 1 [17] [16] [15] [14] [13] [12] [11] [10] F-1-3 [1] Feeder [2] Control panel [3] Toner access cover [4] Front cover [5] Right front deck [6] Cassette 3 [7] Cassette 4 [8] Left front deck [9] Left cover (paper) [10] Environment switch [11] Cassette heater switch [12] Leakage breaker...

-

Page 37: Cross-Section

Chapter 1 [18] [19] [29] [20] [28] [21] [27] [22] [26] [23] [25] [24] F-1-4 [18] Reader right cover [19] Reader rear cover [20] Read cover (upper) [21] Right cover (upper rear) [22] Rear cover (lower) [23] Main power switch [24] Right cover (lower rear) [25] Right cover (lower) [26] Right door unit (lower) - Page 38 Chapter 1 [10] [11] [12] [13] [14] [15] [16] [17] [18] [19] [20] [21] [59] [22] [58] [23] [57] [56] [24] [55] [25] [54] [26] [27] [53] [28] [52] [51] [50] [29] [49] [30] [31] [32] [48] [33] [47] [34] [46] [35] [36]...

-

Page 39: Using The Machine

Chapter 1 [41] Cassette 4 feed roller [42] Cassette 4 separation roller [43] Cassette 4 [44] Cassette 3 [45] Left deck [46] Left deck separation roller [47] Left deck feed roller [48] Left deck pickup roller [49] Fixing lower roller [50] Internal delivery roller [51] External delivery roller [52] Fixing upper roller... - Page 40 Chapter 1 Be sure to go through the shut-down sequence whenever turning off the main power switch. How to Turn Off the Main Power Switch To turn off the main power switch, be sure to go through the following steps to prevent damage to the machine's hard disk: 1) Hold down the control panel power switch for 3 sec or more.

-

Page 41: Control Panel

Chapter 1 F-1-9 1.2.2.3 Control Panel 0015-4310 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N [1] [2] [3] [4] [7] [8] [10] ON/OFF Enargy Saver Reset Help Counter Check Additional Functions PQRS TUV WXYZ Stop Start Display Contrast Clear Processing/Data... - Page 42 Chapter 1 Mode Description use 'system status screen' as initial screen: ON/*OFF give priority to 'device' of 'system status screen': *ON/OFF post-auto clear function *use previous/do not use previous function group order setup: group A, MEAP, group B enable/disable buzzer input sound: *ON/OFF input invalid sound: ON/*OFF replenish alert sound: ON/*OFF...

-

Page 43: Timer Settings

Chapter 1 Mode Description between-job interleaf ON (paper source select) *OFF between-set interleaf ON (setting range between *10 and 9999; paper source select) *OFF right wait time indication copier/box/other (for each, ON/*OFF) Registration of the size of the side paper deck** A3/A4/A4R/B4/B5/11×17/LGL/LTR/LTRR output tray paper mix** *ON/OFF... -

Page 44: System Control Settings

Chapter 1 Mode Description transmission control report print every 100 communications: *ON/OFF print at specific time: *ON/OFF time settings: *00:00 to 23:59 separate transmission/reception: (toggle) ON/*OFF fax transmission result report: *only if error/ON/OFF (specifications setup)** indicate transmission original: *ON/OFF fax communications control report print automatically every 40 communications: *ON/OFF print at specific time: ON/*OFF time setting: *00:00 to 23:59... - Page 45 Chapter 1 Mode Description memory reception end time**: by day, by day of week, *no specification enable/disable remote UI *ON/OFF use SSL: ON/*OFF limit target** address book ID No.: 7 characters max. address book access No. control: ON/*OFF new target limit: ON/*OFF Permit transmission from the fax driver *ON/OFF Entry for confirmation when entering a fax number...

-

Page 46: Copier Specifications

Chapter 1 Mode Description set machine information distribution - register recipient: auto search/register, register, detail info, delete,list printing - auto distribution: every day, by day of week, *no specification user mode setting: ON/*OFF network setup: include, do not include group ID: ON/*OFF address book: ON/*OFF Setting of the print specifications: ON/*OFF - manual distribution setup:... -

Page 47: Transmission/Reception Settings

Chapter 1 Mode Description reset copier specifications Do you want to reset? yes/no (auto sort: ON/face-up delivery: ON/preference key setup: no) 1.2.3.7 Transmission/Reception Settings 0015-4324 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N *Factory default. **Indicated when the appropriate accessory is installed. T-1-11 Mode Description... -

Page 48: Box Settings

Chapter 1 Mode Description reception info record: keep/*do not keep fax basic registration setup** register user telephone number** telephone number: 20 characters max. select line type**: 100V: *20 pps/10 pps/push volume adjust alarm volume: 0 to 8 (84) communication volume: 0 to 8 (*4) off-hook alarm: (*ON/OFF) fax transmission function setup** ECM transmission (*ON/OFF) - Page 49 Chapter 1 *Factory settings. **Indicated in the presence of a specific accessory. T-1-13 Mode Description settings number of copies: 1 to 9999 (*1) duplex: duplex/*simplex pickup default paper size: *A4 (additional 10 possible) default paper type: plain (additional 8 possible) paper size replacement: replace/*do not replace adjust print **super smooth: *use/do not use...

-

Page 50: Address Book Settings

Chapter 1 Mode Description LIPS: *enable/disable N201: *enable/disable ESC-P: *enable/disable 15577: *enable/disable HP-GL: *enable/disable HP-GL/2: *enable/disable Imaging: *enable/disable PDF1.5: *enable/disable **connection recognition: *enable/disable printer settings rest: yes/no 1.2.3.10 Address Book Settings 0015-4329 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N *Factory default. -

Page 51: Voice Guide Settings

Chapter 1 Mode Description search for address simple search (server) server to search: from pull-down from LDAP server already registered (search conditions): name: 128 characters, or 64 2-bye characters e-mail: 12* characters fax: 128 characters detail search server to search: from pull-down from LDAP server already registered (search conditions): *name/e-mail/fax/group/group unit under following: * includes next/does not include next/is identical to next/is not identical to next/start with next/ends with next name, group, group unit: 128 characters, or 64 2-byte characters... -

Page 52: Checks

Chapter 1 F-1-12 3. Platen Board Glass/ADF Reading Glass Wipe the platen board glass [1] and the ADF reading glass [2] with a cloth moistened with water or solution of mild detergent; then, dry wipe them with a dry, soft cloth. -

Page 53: Safety

Chapter 1 F-1-16 3) Check to see that the breaker switch [1] has shifted to the OFF position, thus cutting off the power. F-1-17 4) Turn off the main power switch. 5) Shift the breaker switch [1] back to the ON position. F-1-18 Advise the user that the breaker switch is fully to the ON position. -

Page 54: Handling The Machine's Laser Unit

Chapter 1 F-1-19 The text of the label may differ from model to model. 1.2.5.3 Handling the Machine's Laser Unit 0015-4337 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N Be sure to observe the following whenever you are planning to service the areas around the machine's laser unit: - Do not put a screwdriver or the like that has a high rate of reflection into the laser path. - Page 55 Chapter 1 Copyboard stream reading, fixed reading Body console Light source type xenon lamp (yellow green) Lens type fixed focus Photosensitive medium A-Si drum (80-mm dia.) Image reading method light-receiving element (1 line CCD), CIS Reproduction method indirect electrostatic Exposure method laser light Copy density adjustment auto or manual...

-

Page 56: Function List

Chapter 1 Power consumption (maximum) 1500W (100V), 1920W (120V), 2300W (230V) Power consumption continuous printing (100V, 50Hz, w / accessories ) : 923 Wh (reference only) Ozone Initial: 0.01ppm or less (avr), Later (after 500,000 pages): 0.035 ppm or less (avr) Dimensions 643mm(W) x 743mm(D) x 1207mm(H)(Including an ADF) * Only for Japan (with a capacitor): 643mm(W) x 839mm(D) x... -

Page 57: Paper Types/Printing Speed (K Paper)

Chapter 1 E232 E232A E232B Single-sided Double-sided Single-sided Double-sided Single-sided Double-sided Classification Paper size Deck Multi Deck Multi Deck Multi Deck Multi Deck Multi Deck Multi cassette manual cassette manual cassette manual cassette manual cassette manual cassette manual feed *1 feed feed *1 feed... - Page 58 Chapter 1 Paper feeding position Type Paper size Deck (left/ 3.5 side paper 3.5 large Cassette Manual feed right) deck paper deck Special OHP film A4,A4R,LTR,LTRR paper Postcard A4R deformed, Double postal card, Four- face postcard Label A4,A4R,B4,LTR,LTRR Index (tab) paper A4,LTR Tracing paper A3,B4,A4R,A4,B5R,B5...

- Page 59 Chapter 2 Installation...

- Page 61 Contents Contents 2.1 Making Pre-Checks................................2-1 2.1.1 Selecting the installation space ..............................2-1 2.1.2 Combination Table of Accessories .............................. 2-2 2.1.3 Checking the Contents ................................. 2-3 2.2 Unpacking and Installation ............................2-5 2.2.1 Unpacking and installation procedure ............................2-5 2.2.2 Unpacking ....................................2-5 2.2.3 Installation of Scanner .................................

- Page 62 Contents 2.8.1 Checking Contents ..................................2-24 2.8.2 Installation Procedure ................................2-24 2.8.3 Checking Contents ..................................2-25 2.8.4 Installation Procedure ................................2-25 2.9 Installing the Reader Heater ............................2-25 2.9.1 Checking the Contents ................................2-25 2.9.2 Power off of the host machine ..............................2-25 2.9.3 Installation Procedure ................................

-

Page 63: Making Pre-Checks

Chapter 2 2.1 Making Pre-Checks 2.1.1 Selecting the installation space 0015-4647 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N The conditions of the installation space include the following. Preliminary inspection of the planned installation space would be desired before shipping the machine to the customer. 1. -

Page 64: Combination Table Of Accessories

Chapter 2 100 mm or more 2,482 mm 109 mm 500mm 500mm 2,591 mm 500mm F-2-3 7. This equipment should be installed in a well-ventilated room, however not near the ventilating suction mouth in the room. 8. In the case that several machines are installed at the same area, this machine should be arranged so that this machine does not draw directly the exhaust air from the other machines. -

Page 65: Checking The Contents

Chapter 2 2.1.3 Checking the Contents 0016-8935 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N [10] [11] [12] [13] [14] [15] [16] [17] [18] [19] [20] FU5-8564 2 3 4 1 2 3 4 12 18 11 17 11 17 LEGAL... - Page 66 Chapter 2 T-2-2 iR5075N iR5075 Documentation iR5065N iR5065 iR5055N iR5055 User's Guide License agreement for software Send Trial Kit Release Notes Network Quick Start Guide T-2-3 iR5075N iR5075 CD-ROM iR5065N iR5065 iR5055N iR5055 Tutorial CD ManualCD MEAP Admin. CD-ROM UFR II/PCL Driver/Utility CD-ROM iW MC CD-ROM Printer Guide CD-ROM...

-

Page 67: Unpacking And Installation

Chapter 2 2.2 Unpacking and Installation 2.2.1 Unpacking and installation procedure 0015-4653 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N Take into account the following points when installing this equipment. 1. When transferring the host machine from a low-temperature to a warm place and installing it, dew condensation may occur around the pickup/feed assembly, leading to image faulty reproduction. - Page 68 Chapter 2 Be careful that the caster [2] does not fall out from the skid. F-2-8 5) Remove the cardboard on the skid, and then take out the 2 slope plates [1] installed at the center of the skid. If the slope plate is difficult to remove, displacement of the host machine to the rear edge of the skid makes operation easier.

-

Page 69: Installation Of Scanner

Chapter 2 Make sure to tell user to keep the protection sheet in a safe place because it will be used when moving the host machine elsewhere. F-2-15 5) Close the white sheet. 6) Close the DADF. 2.2.4 Installation of Fixing Assembly F-2-12 0015-4659 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N... -

Page 70: Checking Of Charging Assembly And Dustproof Glass

Chapter 2 F-2-20 2) Remove the screw [1] and the mount [2], and disconnect the connector [3]. F-2-17 4) Peel off the tag tape to open the fixing/delivery assembly [1]. F-2-21 3) While holding the front and rear sides of the transfer/separation charging assembly [1], slide it in the [A] direction;... -

Page 71: Installation Of Developing Assembly

Chapter 2 F-2-23 9) Detach the connector cover [1]. F-2-27 - 1 screw [2] 15) Check the pre-transfer charging assembly. If any dirt or paper powder is attached onto the assembly, clean it with alcohol solutions. 16) Remove the dustproof glass [1]. F-2-24 10) Remove the 2 screws [1] and disconnect the connector [2];... -

Page 72: Installation Of Pickup Assembly

Chapter 2 F-2-29 2) Remove the tape [1], and detach the hopper supply mouth cover [2]. F-2-32 6) Fit the developing assembly pressure unit [1] to [2], and slide it in hori- zontally in the [A] direction; then, shift toward the [B] direction. - 1 screw (binding;... -

Page 73: Attaching Deck Pressure Plate

Chapter 2 Do not shake the toner container. If setting the toner container that has been shaken to the host machine, the toner overflow within the machine may occur. By shaking the container, the toner fluidity increases. As a result, toner is supplied swiftly to the machine with the toner supply operation, causing the foregoing symptoms. -

Page 74: Connecting The Cable

Chapter 2 F-2-40 6) Close the toner replacement cover. When turning on the main power switch without setting toner container, the F-2-43 toner level meter on the control panel shows 25 % or less. Make sure that the 4) Connect the connector [1] of the ADF communication cable. toner container is set in the host machine before turning on the main power switch. -

Page 75: Attaching The Label

Chapter 2 T-2-5 Cassette heater Cassette heater switch ON Cassette heater switch OFF Environment switch ON Environment switch ON Main power switch OFF Main power switch ON F-2-48 2) Attach the cleaning procedure labels [1] [2] for the relevant language. F-2-49 3) Remove the reading cleaning tool [1]. -

Page 76: Turning On The Main Power Switch

Chapter 2 Use the correct power code to mach the location/area of installation. Make -Be sure to attach the inch-series block firmly. sure not to leave unused power code at the site. -Go through this procedure only in case of not using inch-series paper. 2.2.14 Turning On the Main Power Switch 0015-4668 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N... -

Page 77: Changing The Media Size Of The Front Deck (Left/Right)

Chapter 2 Due to the drop of toner from the drum separation claw, there may be a dirty image in the initial 10 sheets. This dirt disappears as copy volume goes on. 2) Check with the user to find out the size of paper to use, and set the paper size of each cassette, and attach the size label to the cassette size plate. -

Page 78: Adjustment Of Image Leading Edge Margin

Chapter 2 <Manual Feeder Tray> 1) Open the manual feed tray. 2) Move the side guide plate [1] to the center, and loosen the 2 screws [2] for the slide guide to adjust the position of the slide guide. image Move the slide guide toward the back = the left margin is reduced Move the slide guide toward the front = the left margin is increased F-2-60... - Page 79 Chapter 2 - 2 screws [2] F-2-67 3) Attach the lower rear right cover removed in the step 1). 2) Store the following parts: - Drum rotational tool [1]: store it along with the collecting toner cap to the hole of the pullout grip at the top of the collecting toner case [2]. <Attaching of the grip cover>...

- Page 80 Chapter 2 Be sure that the front side of the service book case is exposed for 6mm from the front side of the bottom plate [2] of the host machine when attaching the service book case. In case of attaching the service book case without any margin exposed from the bottom plate, it will cause the service book case to run into the rail of the paper deck when mounting the paper deck later.

-

Page 81: Checking The Connection To The Network

Chapter 2 In case of reentering the IP address, turning off and then on the main power is required in order to be enabled. 4) Perform the shutdown sequence so that the main power can be turned off. 5) Turn on the main power switch. 2.3.3 Using the Ping Command 0015-4749 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N... -

Page 82: Relocating The Machine

Chapter 2 address settings, and check with the system administrator to see if the assigned IP address is a valid one. - The connection of the network PCB may be wrong: Check the connection of the network PCB once again. - The network PCB may be faulty. - Page 83 Chapter 2 - When mounting the delivery Tray to the host machine, be sure to attach the See the figure below to make sure the mounting direction of the delivery rollers in the center of delivery roller. roller's protrusion [1]. - When mounting the delivery tray to the host machine, shift tray or finisher should not be mounted.

-

Page 84: Installing The Card Reader

Chapter 2 <Card Reader Attachment-C2> F-2-82 11) Attach the delivery tray bar [1]. F-2-85 Card reader attachment plate 1pc. Joint plate 1pc. Screw 1pc. F-2-83 (small panhead screw; M4X6) 2.7 Installing the Card Reader Screw (RS tightening; M4X10) 2pc. 2.7.3 Power off of the host machine 2.7.1 Notice At Installation 0015-4774 0015-4772... - Page 85 Chapter 2 F-2-86 3) Attach the card reader attachment plate [1]. - Screw (RS tightening; M4X10) [2] 2pc. F-2-90 7) Get the cable [1] out from the side of the host machine. If the cable is difficult to remove, drivers etc. will help make the operation easier.

-

Page 86: Installing For Imageware Accounting Manager

Chapter 2 10) Cut the area [1] of the right cover (upper) with a wire cutter etc. F-2-94 11) Attach the right cover (upper) detached in the step 2). 12) Close the toner replacement cover. 13) Insert the power cable (for the plug). 14) Turn on the main power switch, and then check the display demanding setting of the control card. -

Page 87: Checking Contents

Chapter 2 If it is hard to hook the document tray, loosen the 2 stepped screws and hook it once again. 2.8.3 Checking Contents 0015-8032 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N <Document Tray-M1> F-2-100 If it is hard to hook the document tray, loosen the 2 stepped screws and hook it once again. -

Page 88: Installation Procedure

Chapter 2 How to turn off the main power When turn off the main power, implement the following steps to protect the hard disk of this product. 1) Push the control panel power switch for 3 sec or more. 2) Operate the touch panel following the instruction on the screen of shutdown sequence in order to be ready to turn off the main power switch. -

Page 89: Installing The Cassette Heater

Chapter 2 F-2-106 F-2-110 7) Hold the tab (the bend) [A] of the mirror stay to move the No. 1 mirror 10) In case that the cable [1] is loose, insert the cable clamp [2] to the frame's base [1] to the left until it stops. hole to fix the cable in place. -

Page 90: Power Off Of The Host Machine

Chapter 2 F-2-113 heater unit FM2-4182-000 1pc. cassette stay FL2-3994-000 1pc. screw (M4X6) XB1-2400-609 6pc. 2.10.2 Power off of the host machine 0015-7816 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N How to turn off the main power F-2-115 When turn off the main power, implement the following steps to protect 3) Detach the lower rear cover [1]. - Page 91 Chapter 2 F-2-118 6) Lift the inner unit [1] in Cassette 4, and remove it. 9) Secure the cassette stay [1] in place from the rear side of the host machine. - 2 screws (M4X6) [2]. F-2-119 7) In the same way, remove the inner unit of Cassette 3. 8) Engage the claw [A] of the lead edge onto the long hole [B] of the host machine to attach the cassette stay [1].

-

Page 92: Installing The Deck Heater

Chapter 2 F-2-124 14) Attach the covers etc., by the reverse procedure to detach them. - heat exhaust fan (filter) - lower rear cover - upper rear cover - Secure the reader communication cable in the wire saddle. 15) Fit the inner units in each cassette in place, and then attach the cassettes onto the host machine. -

Page 93: Turning Off The Host Machine

Chapter 2 2.11.2 Turning Off the Host Machine 0016-1684 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N Turning Off the Main Power of the Host Machine When turning off the main power, be sure to go through the following in strict sequence to protect the machine's hard disk: [1] Hold on the power switch on the control panel 3 sec or more. -

Page 94: Turning Off The Host Machine

Chapter 2 2.12.2 Turning Off the Host Machine 0016-1691 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N Turning Off the Main Power of the Host Machine When turning off the main power, be sure to go through the following in strict sequence to protect the machine's hard disk: [1] Hold on the power switch on the control panel 3 sec or more. -

Page 95: Power Off Of The Host Machine

Chapter 2 2.13.3 Power off of the host machine 0015-4783 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N How to turn off the main power When turn off the main power, implement the following steps to protect the hard disk of this product. 1) Push the control panel power switch for 3 sec or more. - Page 96 Chapter 2 F-2-130 4) Remove the face cover plate [1]. (The removed plate is not used after this step.) - 2 screws [2] F-2-131 5) Attach the Voice Board instruction plate [2] to the voice board [1]. - 2 screws (binding; M3X6) [3] F-2-132 Checking the Position of the Slide Switch (SW1) on the Voice Guidance Board The slide switch (SW1) on the Voice Guidance Board is provided as a means of switching frequencies (33 MHz/66 MHz) to suit the transfer speed of the PCI bus.

- Page 97 Chapter 2 33MHz 66MHz 6) Mount the voice board [1] to the PCI Expansion Kit-D2 using the 2 screws [2] removed in step 4). Cautions in mounting - A voice board [1] must be mounted to a specified position. Be sure to mount it to the slot [A] on the Expansion Bus B-1 board. Do not mount it to the slot [B] or [C].

- Page 98 Chapter 2 F-2-133 11) Mount the speaker unit (upper) [1] on the speaker unit (lower), fix them with a screw (binding; M4X6) [2] from beneath. F-2-134 12) Take off the cover [1] from the code guide. F-2-135 13) Peel off the released paper of the code guide [1] and affix it to the host machine as shown in the figure. The right side --- 2 places F-2-136 The rear -- 4 places...

- Page 99 Chapter 2 F-2-137 14) Connect the cable [2] into the speaker unit [1]. F-2-138 15) Run the cable [1] through the cable guide [2] and mount the cable guide cover [3]. There should no excessive bending of the cable. F-2-139 16) Attach the ferrite core [1] to the cable.

- Page 100 Chapter 2 F-2-141 18) Run the cable [1] through the code guide [2] and mount the code guide cover [3]. There should no excessive bending of the cable. F-2-142 19) Connect the power cable to the outlet. 20) Turn ON the main power switch. 21) Check if the voice board is recognized.

-

Page 101: Installing The Wireless Network Interface Adapter

Chapter 2 2.14 Installing the Wireless Network Interface Adapter How to turn off the main power When turn off the main power, implement the following steps to protect the hard disk of this product. 2.14.1 Points to Note When Installing 1) Push the control panel power switch for 3 sec or more. - Page 102 Chapter 2 F-2-146 4) Remove the 2 face cover plates [1]. - 4 screws [2] MEMO: Of the detached 2 face cover plates, one at the wireless LAN board will not be used. F-2-149 7) Attach the parts so far removed. - Face cover plate - Main controller box cover - Upper rear cover...

-

Page 103: Affixing The Label

Chapter 2 F-2-154 13) Connect the MFP antenna cable [1] with the wireless LAN board termi- nal [2]. F-2-151 10) Detach the 5 covers of the cord guide [1]. F-2-152 11) Remove the sheet of the 5 cord guides [1] and put them on the indicated position at the rear side of the host machine. - Page 104 Chapter 2 F-2-156 2-42...

- Page 105 Chapter 3 Basic Operation...

- Page 107 Contents Contents 3.1 Construction ...................................3-1 3.1.1 Functional Construction................................3-1 3.1.2 Wiring Diagram of the Major PCBs ............................3-1 3.1.3 Controlling the Main Motor (M2)..............................3-2 3.2 Basic Sequence ................................3-3 3.2.1 Basic Sequence of Operation (at power-on; 30-sec start-up mode)..................... 3-3 3.2.2 Basic Sequence of Operation (at power-on;...

-

Page 109: Construction

Chapter 3 3.1 Construction 3.1.1 Functional Construction 0015-4341 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N The machine may be divided into the following seven functional blocks: Original Reader controller PCB Original CCD/AP Optical path illumination Reader Control System Original Exposure System Main controller PCB... -

Page 110: Controlling The Main Motor (M2)

Chapter 3 J1031 LCD panel Keypad J130 Inverter IH driver J1041 (LCD) J131 J6802 J6801 J3031 Potential J1113 J1114 J1112 J1110 J1111 control PCB J426 Control panel CPU PCB J107 Duplexing J6801 driver PCB J2302 J1018 Laser scanner J1406 J122 J122 J1015 motor... -

Page 111: Basic Sequence

Chapter 3 J4005 J631 DC power supply Drive circuit Main motor (M2) Clock pulse J108 J632 MAIN_M_CLK DC controller generation MAIN_M_GND circuit MAIN_M_5V Control circuit Reference MAIN_M_ON signal generation MAIN_M_FG circuit F-3-3 3.2 Basic Sequence 3.2.1 Basic Sequence of Operation (at power-on; 30-sec start-up mode) 0015-4347 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N Main power... -

Page 112: Basic Sequence Of Operation (At Power-On; High-Humidity Start-Up Mode)

Chapter 3 Main power switch ON WMUPR PSTBY CNTR 60 sec (approx.) Main motor (M2) Drum motor (M1) Pre-exposure LED (LED1) Primary charging Laser Developing clutch (CL1) Developing bias (DC) Developing bias (AC) Bias roller Pre-transfer charging (DC) Pre-transfer charging (AC) Transfer charging Separation charging (DC) -

Page 113: Basic Sequence Of Operation (At Time Of Copying/Printing)

Chapter 3 Main power switch ON WMUPR PSTBY CNTR 60 sec (approx.) Main motor (M2) Drum motor (M1) Pre-exposure LED (LED1) Primary charging Laser Developing clutch (CL1) Developing bias (DC) Developing bias (AC) Bias roller Pre-transfer charging (DC) Pre-transfer charging (AC) Transfer charging Separation charging (DC) - Page 114 Chapter 3 *1: temperature control under way for fixing standby mode. *2: as in the case of standby, while copying/printing is under way, the fixing target temperature is decreased to suit the passage of time after the end of start-up. T-3-5 Interval Description...

- Page 115 Chapter 4 Main Controller...

- Page 117 Contents Contents 4.1 Construction ...................................4-1 4.1.1 Construction and Mechanisms ..............................4-1 4.2 Construction of the Electrical Circuitry .........................4-1 4.2.1 Main Controller PCB ................................... 4-1 4.2.2 HDD ......................................4-2 4.3 Start-Up Sequence................................4-4 4.3.1 Overview...................................... 4-4 4.3.2 Start-Up Sequence ..................................4-4 4.4 Shut-Down Sequence ..............................4-6 4.4.1 Overview......................................

-

Page 119: Construction

Chapter 4 4.1 Construction 4.1.1 Construction and Mechanisms 0015-4355 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N The machine's main controller block consists of the following and has the following functions: T-4-1 Item Description Main controller PCB Controls system operation, memory, printer unit output, image processing, scanner unit image input processing, rendering, color LCD controller, card reader unit interface, fax image... - Page 120 Chapter 4 J1062 J1040 J1018 J1014 J1060 J1022 J1024 J1023 J1015 J1064 J1002 J1061 BAT1001 J1013 J1059 J1030 J1034 J1063 J1021 J1010 J3000 J1016 J3002 J1017 J1032 J1003 J3001 J1004 J1006 F-4-2 T-4-2 Connector Description Connector Description J1003 DDR SDRAM connection slot J1024 New card reader connector J1004...

-

Page 121: Hdd

Chapter 4 Partition Description TMP_PSS PDL spool TMP_FAX Ensures fax reception. APL_SEND Stores user data (address book, transfer settings). APL_MEAP Stores MEAP applications. APL_GEN Mode memory data, standard mode data History (e.g., print job history) iFax image data Fax image data Other IMG_MNG Stores file management table, profile. -

Page 122: Chapter 11 Meap

Chapter 4 SYSTEM Language MEAP G3FAX *1 SDICT RCON Reader Unit DC Controller PCB BOOT G3FAX *2 DCON G3 FAX Unit Main Controller PCB F-4-4 *1: 1-port FAX *2: 2-port FAX 4.3 Start-Up Sequence 4.3.1 Overview 0015-4358 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N The system software used to control the machine is stored on the HDD. - Page 123 Chapter 4 - Self Diagnosis Program (interval 1) The self-diagnosis program is run by the CPU on the main controller PCB when the main power switch is turned on. The program is used to check the condition of the image memory (SDRAM) and the HDD. The machine will indicate an error code if it finds a fault while running the program.

-

Page 124: Shut-Down Sequence

Chapter 4 - While the Boot Program Is Being Run Image memory (SDRAM) System area Image data area System software Boot Self-diagnosis program program BootROM Main controller PCB : access to the program during execution. : flow of the system program. F-4-8 4.4 Shut-Down Sequence 4.4.1 Overview... -

Page 125: Construction Of The Image Processing Module

Chapter 4 Other iR machine Original Copy Scan SEND PullScan E-Mail PDL Print Image data Print F-4-10 4.5.2 Construction of the Image Processing Module 0015-4363 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N The machine's major image processing is executed by the main controller PCB. The following shows the construction of the modules associated with image processing: Reader controller Reader unit... -

Page 126: Compression/ Extension/ Editing Block

Chapter 4 Reader unit Main controller PCB Enlargement/reduction Edge emphasis -intensify-to-density conversion -density adjustment (F adjustment) -gamma correction Text mode Film photo mode Text/photo/film photo mode Binary processing (error diffusion) Binary processing (screen processing) To compression/expansion/editing block F-4-12 4.5.4 Compression/ Extension/ Editing Block 0015-4365 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N Here, image data is processed for compression, extension, and editing. -

Page 127: Flow Of Image Data

Chapter 4 Main controller PCB Compression/expansion/editing block Binary density conversion Enlargement/reduction Smoothing For PDL data, Thickening when fine line processing is ON To DC controller PCB F-4-14 4.6 Flow of Image Data 4.6.1 Flow of Image Data According to Copy Functions 0015-4367 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N The following is the flow of image data when the Copy Function is in use:... -

Page 128: Flow Of Image Data For The Send Function

Chapter 4 Printer unit Main controller PCB Image processing block for printer unit SDRAM Data rotation Data compression F-4-16 4.6.3 Flow of Image Data for the SEND Function 0015-4369 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N The following is the flow of image data when the SEND function is in use. -

Page 129: Flow Of Image Data For The Fax Reception Function

Chapter 4 Reader unit Main controller PCB Image processing block for reader unit SDRAM Compression Compression Expansion Image processing block for fax Resolution conversion Super G3 Fax Board F-4-18 4.6.5 Flow of Image Data for the Fax Reception Function 0015-4371 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N The following is the flow of image data when the fax reception function is in use: Super G3 Fax Board... -

Page 130: Flow Of Image Data For The Pdl Function

Chapter 4 4.6.6 Flow of Image Data for the PDL Function 0015-4372 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N The following is the flow of image data when the PDL function is in use: Ethernet Main controller PCB Rendering processing block SDRAM... -

Page 131: Parts Replacement Procedure

Chapter 4 4.7.2 Main Controller PCB 4.7 Parts Replacement Procedure 4.7.2.1 Before Removing the Main Controller PCB 0015-6366 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N 4.7.1 Main Controller Box 1) Detach the rear cover (upper). (page 10-13)Reference[Removing the 4.7.1.1 Before Removing the Main Controller Box Rear Cover (Upper)] 2) Detach the main controller box cover. -

Page 132: When Replacing The Main Controller Pcb

Chapter 4 F-4-27 [1] Boot ROM [2] Hard disk [3] Image memory (SDRAM) [4] Counter memory PCB 4.7.3 SDRAM 4.7.3.1 Before Removing the SDRAM 0015-6371 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N F-4-25 4) Disconnect all the connectors of the main controller PCB, and remove the 1) Detach the rear cover (upper). -

Page 133: Hdd

Chapter 4 IMG_MNG/APL_MEAP/APL_GEN/APL_SEND). (For details, see the de- scriptions given for upgrading.) - Downloading the system software Using the SST, download the following: System, Language, RUI, MEAP- CONT (Meap content), SDICT (OCR dictionary), KEY (key/certificate for encrypted communication), TTS (audio dictionary). 4.7.6 Video PCB 4.7.6.1 Before Removing the Video PCB 0015-8243... -

Page 134: Controller Fan

Chapter 4 F-4-33 4.7.7 Controller Fan 4.7.7.1 Before Removing the Controller Cooling Fan 0015-6383 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N 1) Detach the right cover (upper rear).(page 10-12)Reference[Removing the Right Cover (Upper Rear)] 2) Detach the right cover (upper). (page 10-12)Reference[Removing the Right Cover (Upper)] 3) Remove the right door unit (upper). - Page 135 Chapter 5 Original Exposure System...

- Page 137 Contents Contents 5.1 Construction ...................................5-1 5.1.1 Specifications, Controls, and Functions............................5-1 5.1.2 Major Components..................................5-1 5.1.3 Construction of the Control System............................. 5-2 5.1.4 Reader Controller PCB ................................5-3 5.2 Basic Sequence ................................5-4 5.2.1 Basic Sequence of Operations ..............................5-4 5.2.2 Basic Sequence of Operation in Response to a Press on the Start Key ..................5-5 5.3 Various Control................................5-5 5.3.1 Controlling the Scanner Drive System ............................

- Page 138 Contents 5.4.6 Memory PCB ..................................... 5-21 5.4.6.1 Before Removing the Memory PCB................................5-21 5.4.6.2 Removing the memory PCB ..................................5-21 5.4.7 Inverter PCB ....................................5-21 5.4.7.1 Before removing the inverter PCB ................................5-21 5.4.7.2 Removing the Inverter PCB..................................5-21 5.4.7.3 After Replacing the Inverter PCB................................. 5-22 5.4.8 Scanner Motor....................................

-

Page 139: Construction

Chapter 5 5.1 Construction 5.1.1 Specifications, Controls, and Functions 0015-4373 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N The specifications, controls, and functions of the machine's original exposure system are as follows: T-5-1 Item Description Scanning lamp YG xenon lamp Original scanning book mode: by moving the scanner... -

Page 140: Construction Of The Control System

Chapter 5 Item Notation Description Reader controller PCB controls the reader unit as a whole, performs digital image processing Scanner motor Original size Original size sensor (inch) sensor (A/B) Reader controller Interface PCB Memory PCB CCD unit Reader cooling fan open/closed sensor 1 Inverter PCB Scanner... -

Page 141: Reader Controller Pcb

Chapter 5 Scanner Scanner motor motor control To ADF Reader controller To printer To printer (main controller) CCD unit Interface PCB Reader cooling fan open/closed sensor 1 Scanner HP sensor open/closed sensor 2 Reader controller Interface PCB To printer Scanning (main controller) lamp activation control... -

Page 142: Basic Sequence

Chapter 5 Image processing (shading correction) Scanner motor Storage of system software Printer (flash ROM) unit (not used) J201 J203 J202 DC24V J209 DC13V DC5V DC3.3V (CPU) J210 J206 J205 J207 J208 J204 (not used) Backup of service mode settings Original size Original size sensor (AB) -

Page 143: Basic Sequence Of Operation In Response To A Press On The Start Key

Chapter 5 Main power switch ON STBY SREADY Forward Reverse - shift shading Reader motor - fixed shading - white plate dust Scanning lamp detection control - shading correction HP sensor Scanner unit position HP (shading position) (shading position) CCD output correction F-5-6 5.2.2 Basic Sequence of Operation in Response to a Press on the Start Key 0015-4384... -

Page 144: Controlling The Scanner Motor

Chapter 5 Reader Interface controller Scanner motor Light-blocking plate (forward) Scanning lamp (reverse) Scanner HP sensor No.2 mirror No.1 mirror base base F-5-9 [1] Scanner Motor M501 Drive Signal starts/stops the motor; controls the direction and speed of its rotation [2] Scanner HP Detection Signal detects the presence of the No. -

Page 145: Enlargement/Reduction

Chapter 5 ERROR CODE: E202 (HP detection error) -0001: when the No. 1 mirror base is moving forward, it fails to reach the HP sensor within a specific period of time -0002: when the No. 1 mirror base is moving in reverse, it fails to reach the HP sensor within a specific period of time SERVICE MODE: COPIER>ADJUST>ADJ-XY>ADJ-X (scanner image leading edge position adjustment) Enter a value to adjust the image leading edge position. -

Page 146: Controlling The Scanning Lamp

Chapter 5 Description 50-99% increases the speed at which the original is moved. e.g., at 50%, collects the image at twice the speed for 100%. 100% 325 mm/sec 101-200% decreases the speed at which the original is moved. e.g., at 200%, collects image data at 1/2 the speed for 100%. The following shows the speeds at which the original is moved: 100% 200%... -

Page 147: Detecting The Size Of Originals

Chapter 5 Electrode Electrode Fluorescent Opening material Glass tube Electrode Electrode F-5-15 5.3.3.3 Controlling the Activation 0015-4399 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N The machine turns on or off the scanning lamp using the drive signal (XE_ON) from the CPU on the reader controller PCB. In response to the signal, the inverter PCB generates high-frequency high voltage in the activation control circuit using the drive voltage (+24 V) supplied by the reader controller PCB, thus turning on the xenon lamp. -

Page 148: Overview Of Operation

Chapter 5 T-5-7 Result of identification Result of movement original absent original present original present original present Note: Change in the Signal in Response to ADF Open -> Closed change present: no other: yes The OR argument is applied to the outputs at 2 points. 2. - Page 149 Chapter 5 Scanning lamp Original sensor Point of detection 1 Point of detection 2 Platen Point of detection 3 glass Reader unit Point of detection 4 CCD point of original detection F-5-19 2. ADF Being Opened No.1 mirror base: moves to a specific point of original detection scanning lamp: off original sensor: off (external...

-

Page 150: Dirt Sensor Control

Chapter 5 AB-Configuration Inch-configuration CCD point CCD point Original Original of detection of detection Original Original size size sensor 3 sensor 1 11"x17" LTRR STMTR STMT absent change absent :change present none F-5-25 5.3.5 Dirt Sensor Control 5.3.5.1 Dust Detection in Stream Reading Mode 0015-4409 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N The machine uses the dust detection control mechanism to check for dust on the platen glass and the ADF platen roller, thus preventing reproduction of dust, if any,... -

Page 151: White Plate Dust Detection Control

Chapter 5 0.5mm 0.5mm 0.5mm 0.5mm At the end of a job pattern 1 pattern 2 pattern 3 pattern 4 pattern 5 At the start of a job F-5-27 If dust is detected at all 5 points (A, B, C, D, E), the machine will issue an alert in response to the placement of an original in the ADF, thus promoting the user to clean the points. -

Page 152: Image Processing

Chapter 5 Start key SCAN SCAN Dust detection control Dust detection control F-5-28 2. Particulars of Control - White Plate Dust Detection The machine compares the data on the light reflected by the white plate at time of fixed shading and shift shading to check for dust on the white plate while at the same time identifying the coordinates and width of the area of dust. -

Page 153: Ccd Drive

Chapter 5 CCD (1 line each for R, G, and B) J101 J204 A12V Odd-numbered Even-numbered pixel pixel J204 CCD control signal Analog image CCD drive signal control Reader controller Gain correction Even-numbered Analog image data pixels process Digital image Odd-numbered conversion signal... -

Page 154: Shading Adjustment

Chapter 5 The output of the CCD may not necessarily be even because of the following factors even if the density of the original is perfectly even: (1) variation in the sensitivity of the individual pixels of the CCD (2) difference in the degree of light passing through the center of the lens and through its edge (3) difference in the intensity of light between the center and ends of the scanning lamp (4) deterioration of the scanning lamp The machine executes shading correction to make up for the variation in the output of the CCD. -

Page 155: Parts Replacement Procedure

Chapter 5 5.4 Parts Replacement Procedure 5.4.1 CCD Unit 5.4.1.1 Before Removing the CCD Unit 0015-4798 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N 1) Detach the copyboard glass. (page 5-18)Reference[Removing the Copyboard Glass] 5.4.1.2 Removing the CCD Unit 0015-4801 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N 1) Detach the CCD unit cover [2]. -

Page 156: Copyboard Glass

Chapter 5 3-2) ADF white level adjustment (COPIER > FUNCTION > CCD > DF- Right Cover (Upper)] 3) Detach the reader right cover. (page 10-17)Reference[Removing the WLVL1/2) Reader Right Cover] 4) Detach the left cover (upper). (page 10-12)Reference[Removing the Left Cover (Upper)] Be sure to perform white plate data adjustment before performing ADF 5) Detach the reader left cover. -

Page 157: When Replacing The Scanning Lamp

Chapter 5 5.4.4.2 Removing the Reader Controller PCB the new lamp. 0015-4823 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N 4) Slide the No. 1 mirror base [1] to the right so that it matched against the cut-off [2] of the frame. -

Page 158: After Replacing The Reader Controller Pcb

Chapter 5 cover) a-1. image read start position adjustment (X direction; in fixed reading mode) COPIER>ADJUST>ADJ-XY>ADJ-X a-2 image read start position adjustment (Y direction; in fixed reading mode) COPIER>ADJUST>ADJ-XY>ADJ-Y a-3 shading position adjustment (in fixed reading mode) COPIER>ADJUST>ADJ-XY>ADJ-S a-4 feeder mode main scanning position adjustment COPIER>ADJUST>ADJ-XY>ADJ-Y-DF a-5 ADF stream reading CCD reading position COPIER>ADJUST>ADJ-XY>STRD-POS... -

Page 159: Before Removing The Memory Pcb

Chapter 5 F-5-58 F-5-55 How to disconnect the flat cable Slide the locking lever [1] in the direction of the arrow; then, disconnect the flat cable [2]. F-5-59 2) Detach the memory PCB [2]. - 10 Screw [1] F-5-56 3) Detach the interface PCB [2]. - 6 Screw [1] F-5-60 5.4.7 Inverter PCB... -

Page 160: After Replacing The Inverter Pcb

Chapter 5 5.4.7.3 After Replacing the Inverter PCB 0015-9958 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N Execute the following in the service mode. 1) White plate data adjustment (COPIER > FUNCTION > CCD > CCD- ADJ). -

Page 161: Mounting The Scanner Motor

Chapter 5 1) Detach the reader rear cover. (page 10-18)Reference[Detaching the Reader Rear Cover] 5.4.9.2 Removing the ADF Open/Close Sensor 0015-4839 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N 1) Disconnect the connector [1]. F-5-67 4) Detach the scanner motor [2]. - 1 Connector [1] F-5-71 2) Detach the reinforcing plate [2]. -

Page 162: Original Size Sensor

Chapter 5 5.4.11 Original Size Sensor 1) Detach the reinforcing plate [2]. - 4 Screw [1] 5.4.11.1 Before Removing the Original Size Sensor 0015-4842 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N 1) Detach the copyboard glass.(page 5-18)Reference[Removing the Copy- board Glass] 5.4.11.2 Removing the original size sensor 0015-4845... -

Page 163: Cooling Fan

Chapter 5 2) Detach the right cover (upper). (page 10-12)Reference[Removing the Right Cover (Upper)] 3) Detach the reader right cover. (page 10-17)Reference[Removing the Reader Right Cover] 4) Detach the left cover (upper). (page 10-12)Reference[Removing the Left Cover (Upper)] 5) Detach the reader left cover. (page 10-17)Reference[Removing the Reader Left Cover] 6) Detach the reader front cover. - Page 164 Chapter 5 - 1 Screw [1] F-5-88 6) Detach the interface PCB mount [4]. - Connector [1] 9pc. - Flat cable [2] 1pc. - Screw [3] 9pc. F-5-85 F-5-89 F-5-90 7) Detach the memory PCB mount [4]. - Connector [1] 1pc. F-5-86 - Flat cable [2] 1pc.

- Page 165 Chapter 5 F-5-92 8) Open the 2 wire saddles [1]. 9) Detach the motor cover [3] together with the harness. - Screw [2] 4pc. F-5-96 13) Free the harness from the wire saddle [3]. - 2 Connector [1] - 1 Snap band [2] F-5-93 10) Free the harness from the wire saddle [1], and detach the motor frame [3].

-

Page 166: Fitting The Scanner Drive Cable

Chapter 5 F-5-99 In the next steps, draw mark-off lines before removing the screw. 16) Remove the 2 cable fixing screws [2] of the No. 1 mirror base [1]. 17) Remove the cable fixing spring [3]. F-5-101 18) Free the 2 hooks [4] of the cable from the right side of the reader unit frame. -

Page 167: Waste Toner Box Holder

Chapter 5 F-5-103 2) Arrange the mirror positioning tool so that it is ready for use in the ma- chine (by changing the pin position; FRONT). F-5-106 4) Secure the end of the cable that has temporarily been fixed in place on the hook of the reader unit frame. - Page 168 Chapter 5 F-5-108 4) Detach the collecting toner bottle holder [2]. - 2 Screw [1] Take care not to spill the collecting toner. F-5-109 5-30...

- Page 169 Chapter 6 Laser Exposure...

- Page 171 Contents Contents 6.1 Construction ...................................6-1 6.1.1 Overview...................................... 6-1 6.1.2 Major Components..................................6-1 6.2 Basic Sequence ................................6-2 6.2.1 Basic Sequence of Operation (laser exposure) ..........................6-2 6.3 Various Controls ................................6-2 6.3.1 Controlling the Laser Activation Timing............................. 6-2 6.3.1.1 Generating the Sync Signal .....................................6-2 6.3.1.2 Flow of the Sync Signal ....................................6-2 6.3.2 Controlling the Intensity of Laser Light ............................

-

Page 173: Construction

Chapter 6 6.1 Construction 6.1.1 Overview 0015-4421 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N The machine's laser exposure system consists of the laser unit that serves as the source of light and the laser scanning unit that uses a polygon mirror to control the beam of laser light (for main scanning direction). -

Page 174: Various Controls

Chapter 6 6.2 Basic Sequence 6.2.1 Basic Sequence of Operation (laser exposure) 0015-4424 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N Main power switch ON Start key ON WMUP CNTR WLSTR STBY INTR PRINT LSTR STBY Laser scanner motor(M15)* Half speed... -

Page 175: Apc Control

Chapter 6 The laser driver circuit serves to drive the semi-conductor laser with reference to the laser drive signal (LD) coming from the DC controller PCB. The laser drive circuit is associated with the following items of control: - laser activation control - laser intensity control (APC control) - laser intensity control to suit the drum surface potential The various signals have the following meanings and functions:... -

Page 176: Controlling The Laser Scanner Motor

Chapter 6 Video PCB DC controller Laser Driver PCB J121 J101 CTL0 CTL0 Laser CTL1 CTL1 Driver CTL2 CTL2 APC-SEL APC-SEL F-6-5 6.3.3 Controlling the Laser Scanner Motor 6.3.3.1 Controlling the Laser Scanner Motor 0015-4472 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N The machine controls the laser scanner motor so that the motor always rotates at a specific speed. -

Page 177: Parts Replacement Procedure

Chapter 6 2) Turn off and then back on the main power switch. 6.4 Parts Replacement Procedure 6.4.1 Laser Scanner Unit 6.4.1.1 Removing the Laser Scanner Unit 0015-4863 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N 1) Open the right door unit (upper);... - Page 179 Chapter 7 Image Formation...

- Page 181 Contents Contents 7.1 Construction ...................................7-1 7.1.1 Overview...................................... 7-1 7.1.2 Major Components..................................7-1 7.2 Image Formation Process...............................7-1 7.2.1 Overview...................................... 7-1 7.3 Basic Sequence ................................7-2 7.3.1 At Power-On ....................................7-2 7.3.2 At Time of Printing ..................................7-3 7.4 Potential Control ................................7-3 7.4.1 Overview...................................... 7-3 7.4.2 Copier/Printer Potential Control ..............................

- Page 182 Contents 7.10.1.1 Before Removing Process Unit................................... 7-20 7.10.1.2 Removing Process Unit ..................................... 7-20 7.10.1.3 Mounting Process Unit ....................................7-20 7.10.2 Pre-Exposure Lamp ................................. 7-21 7.10.2.1 Before Removing Pre-Exposure Lamp ..............................7-21 7.10.2.2 Removing Pre-Exposure Lamp .................................. 7-21 7.10.2.3 Cleaning Primary Toner Blocking Sheet ..............................7-21 7.10.3 Primary Charging Assembly..............................

- Page 183 Contents 7.10.18.1 Before Removing Separation Claw Holder ..............................7-30 7.10.18.2 Removing Separation Claw Holder .................................7-30 7.10.19 Potential Sensor Unit ................................7-31 7.10.19.1 Outline........................................7-31 7.10.19.2 Before Removing Potential Sensor Unit ..............................7-31 7.10.19.3 Removing Potential Sensor Unit ................................7-31 7.10.20 Charging Wire..................................7-31 7.10.20.1 Outline........................................7-31 7.10.20.2 Routing Charging Wire ....................................7-31 7.10.20.3 Routing Grid for Primary Charging Assembly ............................7-32 7.10.20.4 Adjusting Height of Charging Wire .................................7-32...

-

Page 185: Construction

Chapter 7 7.1 Construction 7.1.1 Overview 0015-4473 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N The following shows the functions of and the methods used by the machine's image formation system: T-7-1 Item Description Photosensitive drum amorphous silicon (80-mm dia. -

Page 186: Basic Sequence

Chapter 7 T-7-2 step 1 pre-exposure step 2 primary charging (positive DC) step 3 laser exposure* step 4 development (AC + positive DC) step 5 transfer (negative DC) step 6 separation (AC + positive DC) step 7 fixing step 8 drum cleaning *Toner is deposited. -

Page 187: At Time Of Printing

Chapter 7 7.3.2 At Time of Printing 0015-4477 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N Start key ON STBY INRT PRINT LSTR STBY Main motor (M2) Drum motor (M1) Laser activation Pre-exposure LED Primary charging Grid bias Developing clutch (CL4) Developing bias (AC) - Page 188 Chapter 7 A. Timing and particulars of potential control 1. At the time of warm-up The machine's potential control consists of copier potential control mechanisms and printer potential control mechanisms. The machine uses VD=390V for both copier and printer control mechanisms. The timing of potential control is as follows: T-7-3 At time of warm-up...

- Page 189 Chapter 7 COPIER>OPTION>BODY>PO-CNT (enable/disable potential control) 0: disable potential control 1: enable potential control 2. In the service mode The following settings may be made for potential control executed 10 min and 60 min after the main power switch is turned on and when the door is opened and closed: COPIER>OPTION>BODY>PO-CNTMD: [1] off (default): disable potential control [2] short mode: decrease the length based on potential attained by executing either of the 2 modes...

-

Page 190: Determining The Primary Current

Chapter 7 COPIER> FUNCTION> DPC>OFST (adjusting potential sensor offset) For the method of adjustment, see "Standards and Adjustments." 7.4.3 Determining the Primary Current 0015-4481 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N To measure the dark area potential (VD) for the first time after the power switch is turned on, the machine uses the most recently measured current level, and meas- ures the drum surface potential using the potential sensor. -

Page 191: Apc Correction

Chapter 7 Potential sensor Photosensitive Developing drum cylinder Fixing assembly temperature 195 C 200 C WMUP WMUPR STBY Potential sensor Laser output Primary charging determined current determined Laser Secondary charging Resulting Vpc Vpc potential Potential control sequence start F-7-11 7.4.6 APC Correction 0015-4484 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N Changes in the laser output cause changes in the surface potential. -

Page 192: Charging Mechanism

Chapter 7 1. Adjusting the Density for Copying The machine increases the developing bias to decrease the copy density. If increased in excess, the bias can cause light images; if decreased in excess, on the other hand, the background can developing fogging. In light of this, the machine executes density processing using changes in the developing bias and image processing (binary density processing). -

Page 193: Primary Charging Mechanism

Chapter 7 Pre-exposure lamp PRE_LED_ON* [1] F-7-13 The following is the signal associated with the mechanism: [1] Pre-exposure LED control signal; when '0', LED goes on 7.5.2 Primary Charging Mechanism 7.5.2.1 Overview 0015-4488 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N The following items are associated with the primary charging control system: 1. -

Page 194: Others

Chapter 7 PRIMARY_CLEAN_OUT1 [1] PRIMARY_CLEAN_OUT2 [2] Wire Primary charging wire cleaning motor (M6) Wire cleaner Primary changing assembly F-7-15 The following signals are associated with the mechanism: [1] Primary charging wire cleaning motor reverse direction signal; when '1', the wire cleaner moves toward the rear. [2] Primary changing wire cleaning motor normal direction signal;... -

Page 195: Pre-Transfer Charging Mechanism

Chapter 7 DC -1000V HVT_ROLLER_BIAS Dust-collecting roller Scraper F-7-16 The following signal is associated with the mechanism: [1] dust-collecting roller bias remote signal; if '1', the dust-collecting roller bias turns on. 7.5.4 Pre-Transfer Charging Mechanism 7.5.4.1 Overview 0015-4492 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N The following items are associated with the pre-transfer charging control system: 1. -

Page 196: Pre-Transfer Charging Assembly Cleaning Mechanism

Chapter 7 COPIER>OPTION>BODY>FUZZY (turning on/off fuzzy control) 0: enable fuzzy control (default) 1: low humidity mode (for pre-transfer charging current level lower than standard) 2: normal humidity mode 3: high humidity mode (for pre-transfer charging current higher than standard) When set to '1' through '3', the machine executes the appropriate modes independently of the reading of the environment sensor. 7.5.4.3 Pre-Transfer Charging Assembly Cleaning Mechanism 0015-4495 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N... -

Page 197: Detecting The State (Full) Of The Collecting Toner Case

Chapter 7 Drum cleaner thermistor Pre-exposure lamp (LED) Cleaning blade Auxiliary roller Separation claw Collecting toner Magnet roller feedscrew F-7-20 7.6.2 Detecting the State (full) of the Collecting Toner Case 0015-4498 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N The following shows the control mechanism used to see if the collecting toner case has become full: DRUM_M_FG DRUM_M_ON... -

Page 198: Drum/Separation Claw Bias Control

Chapter 7 reading reaches '250,000'. 7.6.3 Drum/Separation Claw Bias Control 0015-9606 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N Since the separation claw contacts the drum, toner caught by the separation claw can fall in the feeder path as the machine is getting aged. Such events can cause the soiled back or faulty images. -

Page 199: Detecting The Toner Level And Controlling Toner Supply

Chapter 7 AC output 1200Vpp HVT_DEV_BIAS _DC [1] HVT_DEV_BIAS Developing cylinder _DC [2] F-7-24 The following signals are used in association with the developing bias control mechanism: [1] Developing DC bias current control signal; controls the DC component of the developing bias generated by the high-voltage power supply PCB. [2] turns on/off the developing bias current output. -

Page 200: Transfer Mechanism

Chapter 7 Toner Supply Sequence The toner inside the developing assembly is monitored by the developing assembly toner level sensor (TS1); when the toner inside the developing assembly falls below a specific level, the developing assembly toner level signal goes '0' so that the DC controller PCB recognizes it. If the DC controller PCB detects the developing assembly toner level signal for 0.3 sec or more, it generates the hopper motor drive signal so that the hopper as- sembly will start supplying toner. -

Page 201: Transfer Charging Assembly Cleaning Mechanism

Chapter 7 Low temperature High temperature F-7-28 SERVICE MODE: COPIER>OPTION>BODY>FUZZY (turning on/off fuzzy control) 0: turns off fuzzy control (default) 1: low humidity mode (for lower transfer charging current than standard) 2: normal humidity mode 3: high humidity mode (for higher transfer charging current than normal) When set to '1' through '3', the machine executes the appropriate modes independently of the reading of the environment sensor. -

Page 202: Separation Mechanism

Chapter 7 COPIER> OPTION> BODY> TR-SP-C2 (switching over the transfer/separation output value for pickup from the left deck) COPIER> OPTION> BODY> TR-SP-C3 (switching over the transfer/separation output value for pickup from the cassette 4) COPIER> OPTION> BODY> TR-SP-C4 (switching over the transfer/separation output for pickup from the manual feed tray) COPIER>... -

Page 203: Others

Chapter 7 SERVICE MODE: COPIER> OPTION> BODY> FUZZY (turning off/on fuzzy control) 0: enable fuzzy control (default) 1: low humidity mode (for higher pre-transfer charging current than normal) 2: normal humidity mode 3: high humidity mode (for higher pre-transfer charging current than normal) If '1' through '3' is set, the machine executes the individual modes independently of the reading of the environment sensor. -

Page 204: Parts Replacement Procedure

Chapter 7 7.10 Parts Replacement Procedure 7.10.1 Process Unit 7.10.1.1 Before Removing Process Unit 0015-6484 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N 1) Detach the front cover. (page 10-13)Reference[Removing the Front Cover] 2) Detach the toner supply cover. (page 10-14)Reference[Removing the Toner Supply Cover] 3) Remove the primary fan duct. -

Page 205: Pre-Exposure Lamp

Chapter 7 F-7-39 2) Remove the pre-exposure lamp unit [3]. - 1 connector [1] - 2 screws [2] F-7-40 7.10.2.3 Cleaning Primary Toner Blocking Sheet 0016-0073 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N F-7-37 1) Remove the process unit. 2) After sliding the process unit into the machine, insert the screw [2] by in- 2) Remove the potential sensor rail stay [2]. -

Page 206: Pre-Transfer Charging Assembly

Chapter 7 to the direct rays of the sun. [3] Do not place the process unit or the photosensitive drum in an area sub- ject to high or low temperature or humidity or where temperature or hu- midity tends to change rapidly. [4] Do not place the process unit or the photosensitive drum in an area sub- ject to dust, ammonium gas, or organic solvent/gas. -

Page 207: Cleaning Photosensitive Drum

Chapter 7 F-7-48 Be careful not to scratch the photosensitive drum when removing it. The bearing at the rear side and the gear at the front side of the photosensitive drum need not be removed. If the temperature of the fixing assembly is 50 deg C or higher when replac- ing the drum unit, be sure to execute the following in the service mode;... -

Page 208: Photosensitive Drum Heater

Chapter 7 Protect the removed photosensitive drum against dirt and scratches by wrap- ping 5 to 6 sheets of paper or the drum protective sheet stored near the col- lecting toner container around the drum. 2) Remove the drum heater unit [1] from the rear. F-7-54 3) Remove the drum heater [2]. -

Page 209: Mounting Cleaning Blade

Chapter 7 F-7-57 2) Detach the cover [2]. F-7-61 - 1 screw [1] 8) Loosen the 5 screws [1], and remove the cleaning blade from the blade [3] Free the harness from the edge saddle, and disconnect the connector [3]. support plate. -

Page 210: Removing Side Seal

Chapter 7 9) Remove the photosensitive drum. (page 7-22)Reference[Removing Photosensitive Drum] Remove collected toner 7.10.9.2 Removing Side Seal 4 8mm 0015-9973 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N 1) Remove the old side seal. 2) Mount the new side seal [1] to the cleaner housing where indicated (both ends). -

Page 211: Hopper Supply Motor

Chapter 7 of the arrow. - 1 screw [1] F-7-69 3) Remove the toner bottle. 4) Remove the hopper assembly [3]. If tilting the hopper assembly, toner will be spilled out; thus, be sure to re- move it without tilting. - 1 connector [1] F-7-71 - 5 screws [2]... -

Page 212: Developing Assembly

Chapter 7 7.10.14 Developing Assembly 7.10.14.1 Removing Developing Assembly 0015-4927 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N The machine’s developing assembly is not equipped with a cover to protect the developing cylinder. If you must remove the developing assembly, be sure not to damage the de- veloping cylinder. -

Page 213: Developing Cylinder

Chapter 7 remove the push-on roll [2]. F-7-84 F-7-80 5) Remove the developing cylinder [2]. - 2 bearings [1] (at the front and the rear) 7.10.15 Developing Cylinder 7.10.15.1 Before Removing Developing Cylinder 0015-6675 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N 1) Remove the developing assembly. -

Page 214: Transfer/Separation Charging Assembly

Chapter 7 7.10.17 Transfer/Separation Charging Assembly 1) Make sure that the 4 protrusions [1] on the transfer/separation charging as- sembly are correctly fitted into the cut-offs [2] in the fixing/feeding unit. 2) Make sure that the leaf spring [3] of the fixing/feeding unit comes in con- 7.10.17.1 Removing Transfer/Separation Charging tact with the frame of the transfer/separation charging assembly by slid- Assembly... -

Page 215: Potential Sensor Unit

Chapter 7 - 1 screw [1] sembly. 2) Detach the cover while pulling the separation claw holder [4] toward the 7.10.20.2 Routing Charging Wire front. - 2 screws [3] 0015-9967 iR5065 / iR 5055 / iR5075 / iR5075N / iR5065N / iR5055N All charging wires (except the grid wire) are routed more or less in the same way;... -

Page 216: Routing Grid For Primary Charging Assembly