Summary of Contents for 6K Products DH0630

-

Page 1: Cover Page

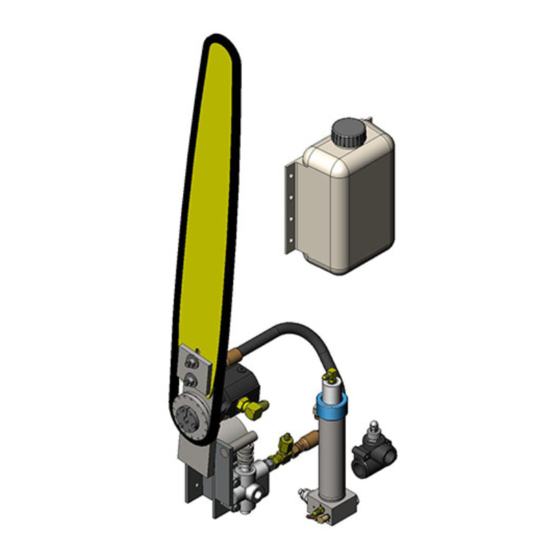

OPERATION AND PARTS MANUAL DH0630 30G36 Simple Saw System Information subject to change without notice. -

Page 2: Safety Precaution

⇒ The information in this manual is subject to change without notification. ⇒ This manual is intended for safe operation and maintenance of the 6K Products, 30G36 Simple Saw System. 6K Products, welcomes any and all suggestions on how to improve this manual or the 30G36 Simple Saw System. -

Page 3: Table Of Contents

Table of Contents Cover page ..................................1 Safety Precaution ................................. 2 Table of Contents ................................. 3 Introduction .................................. 4 Warranty ..................................4 Installation ..................................4 Hydraulic Connections ..............................6 Chain Tension and Sharpening ............................. 7 Sprocket Removal and Replacement ..........................8 Bar Oil Pump Adjustment ............................. -

Page 4: Introduction

Introduction Thank you for purchasing a 6K Products product. Our goal is to provide quality products for your job. This manual contains warranty information, installation information, operation instructions, parts ordering information, and service contact information. Warranty This 6K Products product carries a one year or 2000 hour warranty on the 6K Products designed and built components covering material and workmanship. - Page 5 After assembling the components as shown in figure 2, position the saw bar square to the log, at the correct height with clearance between the bar plate and the side of the largest log and weld down solidly (Fig. 3). The dimensions in figure 3 can be changed as required for your installation.

-

Page 6: Hydraulic Connections

Hydraulic Connections The hydraulic requirements to operate the saw are 29 to 35 gallons per minute at 2000 psi from a fixed displacement hydraulic pump. You must install the pressure relief valve between the hydraulic pump and the selector valve to keep from damaging the hydraulic pump. Figure 4 shows hose connections for correct operation. Fig. -

Page 7: Chain Tension And Sharpening

The Power Beyond Port can connect to another valve for conveyor and clamp, or must go to the filter and tank. The return hose can be #12 or 3/4” diameter for the first two feet. If a longer hose is required it must be #16 or 1” up to twenty feet. -

Page 8: Sprocket Removal And Replacement

Sprocket Removal and Replacement The chain saw sprocket is connected to the shaft with a tapered bushing. To remove the sprocket remove the Cap Screws (Fig. 6, Item 3) and screw them into the Threaded Holes, tighten up to 36 inch pounds to push the Sprocket (Fig. -

Page 9: Bar Oil Pump Adjustment

Bar Oil Pump Adjustments The DH0144 bar oil pump (Fig. 7) is a single acting pump that can pump up to 32 cc, or 1.08 oz., of bar oil per cycle, enough for about 30 seconds of cutting. There is a hose connected to the selector valve manifold (Fig. 4, P4 page 6) that connects to the fitting (Fig. -

Page 10: Operating Instruction

Returning the saw to the up stop will stop the saw chain and reset the bar oil pump. Parts and Service Information For parts and service contact 6K Products. Our hours of operation are 8:00 AM to 4:30 PM, Monday through Friday, Pacific Time excluding holidays. Phone: 360-264-2141... -

Page 11: Main Sub Assembly Parts

MAIN SUB ASSEMBLIES ITEM No. QTY. PART No. DESCRIPTION REMARKS DH0645 30G36 SIMPLE SAW ASSEMBLY DH0144 BAR OIL PUMP ASSEMBLY DH0152 BAR TANK ASSEMBLY VH0014 3/4 NPT 2000 PSI RELIEF VALVE HH0822 #12 JIC SWIVEL RUN TEE HH0947 TUBE REDUCER FM JIC TO M JIC, 892-6-4 DH0634 24"... -

Page 12: Simple Saw Assembly Parts

DH0645 SIMPLE SAW ASSEMBLY... -

Page 13: Bar Oil Pump Assembly Parts

DH0144 BAR OIL PUMP ASSEMBLY... -

Page 14: Bar Oil Tank Assembly Parts

DH0152 BAR OIL TANK ASSEMBLY...