Epson LQ-300 Service Manual

Terminal printer

Hide thumbs

Also See for LQ-300:

- User manual (152 pages) ,

- Service manual (106 pages) ,

- Manual (14 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Summary of Contents for Epson LQ-300

-

Page 1: Service Manual

EPSON TERMINAL PRINTER LQ-300 SERVICE MANUAL EPSON... - Page 2 The contents of this manual are subjects to change without notice. Alleffortshavebeen made toensuretheaccuracy of thecontentsofthis manual. However, should any errors be detected, SEIKO EPSON would greatly appreciate being informed of them. The above notwithstanding SEIKO EPSON can responsibility for any errors in...

- Page 3 THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS. WARNING REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN. MAKE CERTAIN THAT THE SOURCE VOLTAGE IS THE SAME AS THE RATED VOLT- AGE, LISTED ON THE SERIAL NUMBER/RATING PLATE.

- Page 4 Includes a step-by-step guide for product disassembly and assembly. CHAPTER 4. ADJUSTMENTS Includes a step-by-step guide for adjustment. CHAPTER 5. TROUBLESHOOTING Provides Epson-approved techniques for adjustment. CHAPTER 6. MAINTENANCE Describes preventive maintenance techniques and lists lubricants and adhesives required to service the equipment. APPENDIX Describes connector pin assignments, circuit diagrams, circuit board component layout and exploded diagram.

- Page 5 f=”: REVISION SHEET Revision Issue Date Revision Page Rev. A September 28, 1994 1st issue .-..> .$...

- Page 6 TABLE OF CONTENTS CHAPTER 1. PRODUCT DESCRIPTION CHAPTER 2. OPERATING PRINCIPLES AND ASSEMBLY CHAPTER 3. DISASSEMBLY ADJUSTMENTS CHAPTER 4. TROUBLESHOOTING CHAPTER 5. MAINTENANCE CHAPTER 6. APPENDIX - vi -...

-

Page 7: Table Of Contents

CHAPTER Product Description Table of Contents 1.1 FEATURES 1.2 SPECIFICATIONS 1.2.1 Hardware Specifications ........1.2.1.1 Paper Handling Specifications . -

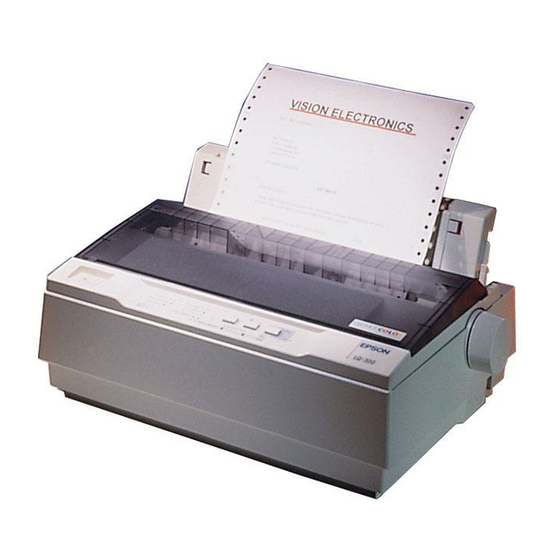

Page 8: List Of Figures

List of Figures Exterior View of the LQ-300....... 1-1 Figure 1-1. ,’:~\ Figure l-2. - Page 9 Product Description LWOO Service Manual 1.1 FEATURES The LQ300 is a small, light-weight, 24pin serial impact dot-matrix color printer suitable for personal use. The major features of this printer are: Fast printing of lo-cpi draft characters at 200 cps Compact design saves precious work space Easy-to-operate panel Quiet printing Two built-in 8-bit parallel interfaces and an EIA-232D serial interface...

-

Page 10: Specifications

Product Description LQ-300 Service Manual SPECIFICATIONS section provides detailed information about the LQ-300. This ,’ 1.2.1 Hardware Specifications Printing method: 5erial impact dot matrix Pin arrangement: 12 x 2, staggered Pin diameter: 0.20 mm (0.0079 inches) L“?”’” ‘ o 5 () - Page 11 LWOO Service Product Description Manual 1.2.1.1 Paper Handling Specifications Paper paths Rear entry (manual insertion or optional CSF) Cut sheet path: Cannot handle multi-part paper using friction feed Rear entry ( push tractor feed using the push tractor unit Continuous paper paths: or pull tractor feed using the pull tractor unit or push-pull tractor feed using both tractor units) Possible, using push tractor unit...

- Page 12 Product Description LQ-300 Service Manual Speed Table 1-3. Feeding Lever Position Feeding 1/6 inch Line Feed Continuous Feed Friction Max 3.6 incheslsec. Max. 94 ins/line o, 1 Typ. 80 ins/line (*) Typ. 3.3 incheshec (*) Tractor Min. 75 ins/line Min. 2.8 inchhec.

- Page 13 Product Description LQ-300 Service Manual Table 1-8. Specifications for Continuous Paper with a Label 63.5 Label size (W x L) mm (min.) x 23.8 mm (min.) [ 2.5 in. (min.) x 15/16 in. (min.)] Width of base paper 101.6 mm -254 mm (4.0 in. x 10,0 in.) Thickness of base 0.07 mm - 0.09 mm (0.0028 in.

- Page 14 LQ-300 Service Manual Product Description Envelopes 3mm[0.12”] 3mm[0.12”] minimum minimum 5.3mm[0.21”] minimum Printable area 13.5mm[0.53*] minimum Envelopes Figure 1-4. Printable Area for Continuous paper 10.51 ], ~ : 203.2 mm [8”], maximum minimum 4----++ .o---- 0 . ., . - ..- ..- .

-

Page 15: Ribbon Specifications

LQ-300 Service Manual Product Description 1.2.1.4 Ribbon Specifications Ribbon cartridge (mono): #7753 #7755 (sub-cartridge) Ribbon cartridge (film): #7768 Ribbon cartridge (color): S015077 Ribbon color: Black, magenta, cyan, yellow Black ribbon life: 2 million characters (48 dots/character) 0.2 million characters dots/character) -

Page 16: Safety Approvals

Product Description LQ-300 Service Manual 1.2.1.8 Safety Approvals Safety standards: U.S. version: UL1950 with D3, CSA22.2 #950 with D3 ,ffq L-. ., European version: EN 60950 ~) IEC950 (SEMKO, DEMKO, NEMKO, SETI) Radio frequency interference: FCC part 15 subpart B class B U.S. - Page 17 8-32 points (units= 2 points) EPSON !%ns serif 8-32 points (units= 2 points) EPSON Roman T EPSON Saris Serif H 8- 32points (units =2points) Drailt 10 cpi; 12 horizontal dots, 24 vertical dots Character matrix: NLQ 10 cpi; 36 horizontal dots, 24 vertical dots...

- Page 18 LWOO Service Product Description Manual Table 1-12. Printing Speed F“ . } Maximum Print Speed [cps] Chg\;gter Printable Printing Mode Columns Mode 3 Mode 1 Mode 2 Draft 10 cpi 12 cpi 15 cpi Draft condensed 17 cpi 20 cpi 10 cpi 12 cpi 15 cpi...

-

Page 19: Interface Specifications

Product Description LQ-300 Service Manual 1.3 INTERFACE SPECIFICATIONS LQ-300 has a Centronics<ompatible parallel interface and an EIA-232D serial interface, one of which can be selected in default setting mode. Auto selection is also available. 1.3.1 Parallel Interface The parallel interface has two modes: . - Page 20 Product Description LQ-300 Service Manual Table 1-13 shows the connector pin assignments and signal functions for the 8-bit parallel interface. c . % Table 1-13. Signal and Connector Pin Assignments for Parallel Interface Pin No. Signal Name Description (!!%”% ‘0’...

- Page 21 Product Description LQ-300 Service Manual 1.3.1.2 Reverse Mode LQ-300 reverse mode supports IEEE-P1284 nibble mode, described in this section. Transmission mode: IEEE-P1284 nibble mode IEEE-P1284 level 1 device Signal level: 36-pin 57-30360 (Arnphenol) or equivalent Adaptable connector: Table 1-14. Signal and Connector Pin Assignments for Parallel Interface Pin No.

-

Page 22: Serial Interface

LQ-300 Service Manual Product Description 1.3.2 Serial Interface The LQ-300 is equipped with an 8-bit serial interface, standard. Data format: EIA-232D serial Synchronization: Asynchronous By DTR protocol, X-ON/X-OFF protocol, ETX/ACK protocol Handshaking: Word length Start bits: 1 bit Data bits:... -

Page 23: Interface Selection

Product Description LQ-300 Service Manual 1.3.3 Interface Selection The printer has 2 interfaces: parallel and serial. These interfaces can be selected manually in default-setting mode or selected automatically. Manual selection One of the two interfaces can be selected in default-setting mode. -

Page 24: Operating Instructions

Product Description LQ-300 Service Manual OPERATING INSTRUCTIONS This section describes control panel operation functions, self-test, hexadecimal dump, paper feed, micro adjustment, and printer initialization methods. 1.4.1 Control Panel Operation The printer control panel contains three non-lock-type push buttons and three LED indicators for easy operation of the various printer functions. -

Page 25: Self-Test Function

Product Description LC?-300 Service Manual Table 1-16. Paper Feeding Functions Friction Feed Tractor Feed Operations Not Paper Out Paper Out State Not Paper Out Paper Out State Load a sheet (*2) Line feed Load a sheet (*2) Eject Press LF/FF and Paper park (*1) —... - Page 26 LQ-300 Service Manual Product Description 1.4.4 Micro Adjustment Function . . . ‘~ To enter adjustment mode, press the Pause button for three seconds, until the printer beeps once . , . . and the operation is available. If the printer state Pause lights bhnk to indicate that the adjustment is not one of the conditions shown below, this operation is ignored.

- Page 27 Product Description LQ-300 Service Manual 1.4.6 Selected Font The combination of two LEDs (1 and2) is used to indicate the selected font. Font To choose one of the seven internal fonts listed on the control panel, press the button. Font Table 1-17.

-

Page 28: Changing The Default Settings

Product Description LQ-300 Service Manual Settings 1.4.8 Printer 1.4.8.1 Selectable Printer Settings The following printer settings can be changed by users in default-setting mode: Character table (Standard): PC437/850/860/861 /863/865 /BRASCII/Abicomp Character table (NLSP): PC437/437 Greek/850 /852/853/855/857/864/866/869 /1S0 Latin IT /1S0 8859-7/Code MJK/Ma.zowia/Bulgaria Page length: 11 /12/ 8.5/ 70/6 inches (A4) - Page 29 LQ-300 Service Manual Product Deacfiption Table 1-19. Default Options Go to Font 1 Light Font 2 Light Pause Light Setting Submenu Tabie 1-20 Character table Blinks Table 1-21 Blinks Page iength Tabie 1-22 Blinks Skip over perforation Tabie 1-22 Biinks...

- Page 30 Product Description LQ-300 Service Manual Table 1-21. Page Length ..~ ..:. Font 1 Light Font 2 Light Pause Light Setting 11 inches 12 inches 8.5 inches i’0/6 inches AGM / Auto Line Feed/ Table 1-22. Skip Over Perforation / Auto Tear Off/...

- Page 31 Product Description LQ-300 Service Manual Table 1-27. Parity Bit Setting Font 1 Light Font 2 Light Pause Light None Even Table 1-28. Data Length Font 1 Light Font 2 Light Pause Light Setting 7 bits 8 bits Rev. A 1-23...

-

Page 32: Main Components

Product Description LQ-300 Service Manual MAIN COMPONENTS The main components of the LQ-300 is designed for easy removal and repair. The main components are: C143 MAIN board: control board C130 PSB/PSE (120 V/230 V) board: power supply board M-5M1O: Printer mechanism Housing 1.5.1 C143... - Page 33 Product Description LQ-300 Service Manual 1.5.3 Printer Mechanism (M-5M1O) The printer mechanism consists of 24-pin impact dot head, PF motor, RF motor, PE sensor, ~ sensor, PG sensor, release lever sensor, etc. Figure 1-10. Printer Mechanism 1.5.4. Housing Assembly This consists of printer cover assembly, edge guide assembly, upper housing, lower housing assembly, etc.

- Page 34 ;“+ - ,.. . ,,-, ’,,,..

- Page 35 CHAPTER 2 Operating Principles Table of Contents 2“1 2.1 PRINTER MECHANISM OPERATION 2.1.1 Printing Mechanism......... 2-1 2.1.2 Carriage Movement Mechanism .

- Page 36 List of Figures Figure 2-1. Printhead Operation Principles ......2-1 Figure 2-2. Carriage Movement Mechanism ......2-2 Figure 2-3.

-

Page 37: Printer Mechanism Operation

Operating Principles LQ400 Service Manual 2.1 PRINTER MECHANISM OPERATION This describes the printer mechanism and explains how it works. section 2.1.1 Printing Mechanism The printing mechanism is composed of the prirdhead, ink ribbon, and ribbon mask. The printhead is a 24pin head for impact dot printing. Each wire has own drive coil, which causes the wire to move in and out of the printhead to print each dot. -

Page 38: Carriage Movement Mechanism

Operating Principles LQ-300 Service Manual 2.1.2 Carriage Movement Mechanism The carriage movement mechanism consists of the carnage assembly, CR motor, timing belt, driven pulley, HP sensor, etc. The CR motor drives the tirnkigbelt. The carnage assembly is connected to the timing belt, which is moved by the CR motor. Figure 2-2 shows the carriage movement mechanism. -

Page 39: Paper Handling Mechanism

LQ-300 Service Manual Oparating Principles 2.1.3 Paper Handling Mechanism During operation, paper is fed to the printer, advanced to the specified position, and normal ejected from the printer. These functions are performed by various paper handling mechanisms, such as the &actors, rollers, and gears. This section describes the paper handling mechanism for this printer. - Page 40 LQ-300 Service Manual Operating Principles Table 2-2. PF Motor Specifications Requirement Category Type 4-phase, 48-pole, PM-type stepping motor Drive Voltage 31.5 -38.5 VDC Coil Resistance 58.5 Q * 5% (per phase, at 25°C, 77°F) Drive Pulse Frequency 800,900, 1000, 1200, 1300 ppS...

- Page 41 Operating Principles L WOO Service Manual Pull Tractor Method The pull tractor advances paper in basically the same way as the push tractor. When the push tractor is installed at the paper exit instead of paper entrance, the tractor functions as a Pull tractor Figure 2-5 sho-ws the pull instead of a push tractor, pulling the paper out of the printer mechanism.

- Page 42 LQ-300 Service Manual Principles Push - Pull Tractor Method ..’.% The push-pull tractor method is a combination of the push method, using the standard tractor, and . .,, the pull method, using an optional tractor. The two tractors operate simultaneously to push and pull the paper through the printer mechanism.

-

Page 43: Ribbon Advance Mechanism

Operating Principles LQ-300 Service Manual Ribbon Advance Mechanism 2.1.4 The ribbon is held between the ribbon advance roller (ribbon driven gear) and the ribbon pressure roIler. When the carriage moves on the CR guide shaft from left to right and vice versa, the timing belt turns the belt driven pulley. -

Page 44: Ribbon Shift Mechanism

Operating Principles LQ-300 Service Manual 2.1.5 Ribbon Shift Mechanism c’ This printer can be equipped with a color upgrade kit to print in color. The printer performs color -’$ printing unidirectionally. The option is composed of the color ribbon shift mechanism. The color . -

Page 45: Platen Gapadjustment Mechanism

Manual Operating Principiea LQ-300 Service Fulcrum Color Ribbon Cartridge CS Lever Black Cyan Magenta Yellow : ~ > Color Cartridge Holder CS Motor Assembly Pinion Color Shift Cam CS Cam Gear Color Shift Cam Follower Figure 2-9. Color Shift Mechanism 2.1.6 Platen Gap Adjustment Mechanism platen gap (the gap between the platen and the printhead) can be adjusted to allow the printer to use paper of different weights or thicknesses. -

Page 46: Power Supply Operation

Operating Principles L(?-300 Service Manual 2.2 POWER SUPPLY OPERATION ‘% ,’ The printer can be powered by either of two power supply boards: the C130 PSB (120 V) or the C130 PSE (230 V) power supply. These boards are the same as the LX-300’S power supplies. The two boards function identically, except for a difference in primary circuitry. -

Page 47: Power Supply Circuit Operation

LQ-300 Service Manual Operating Principle Power Supply Circuit Operation 2.2.2 Figure 2-11 shows a block diagram of the power supply circuitry. When AC power is supplied to the printer from an external power source, a filter cinmit removes the noise. The AC voltage then undergoes full-wave rectification and is smoothed to produce the direct current supply voltage. -

Page 48: Control Circuit

Operating Principles LQ-300 Service Manual 2.3 CONTROL CIRCUIT The control circuit consists of the C143 MAIN board assembly. This section desuibes the major components and explains how the board works. Control Circuit Operation Overview 2.3.1 The printer has a CPU (TMP90C041) that runs at 9.8304 MHz, a gate array (E05B02-type), a PS-RAM (256K-bit), a ROM (4 or 8M-bit), etc. -

Page 49: Power On Reset'circuit

LWOO Service Manual Operating Principles Power On Reset Circuit 2.3.2 When the power supply is turned on and immediately the VL (+9 V) goes up to +7.5 V (typical), the reset IC (IC6) outputs the system RESET signal (LOW). The CPU and gate array receive this LOW level signal from the reset IC and reset themselves. -

Page 50: Home Position Sensor Circuit

Operating Principles LQ-300 Service Manual Home Position Sensor Circuit 2.3.4 This printer has a connector switch to sense the carriage home position. The CPU receives a signal from the HP sensor and recognizes the carriage home position when the printer is turned on. The comector switch is open (OFF) when the carriage is in the home position and is closed (ON) when the carriage is out of home position. -

Page 51: Carriage Motordrivecircuit

L WOO Service Manual Operating Principles Carriage Motor Driver Circuit 2.3.7 Figure 2-18 shows the carriage motor driver circuit. The carriage motor driver uses an open-Ioop, constant-current chopping drive arrangement. The motor is driven with 2-2 phase excitation and 1-2 phase excitation. The MOO-3 (pins 3-6) on the CPU are used to control the phases of stepping motor. -

Page 52: Paper Feed Motordrivecircuit

Operating Principles LC&300 Service Manual Feed Motor Driver Circuit c . , \ 2.3.8 Paper Figure 2-19 shows the paper feed motor driver circuit, an open-loop, constant-voltage drive with 1-2 phase excitation. The ports (pins 7-lo) on the CPU are used to control the stepping motor. The pulse signal from the IC1 controls four tmmsistors and the stepping motor. -

Page 53: Interface Circuit

LQ-300 Service Manual Operating Principles 2.3.10 Interface Circuit Figure 2-21 shows the parallel interface arcuit block diagram. Data from the host computer is latched within the gate array by STROBE signal. The gate array outputs XBUSY signal automatically to stop the host computer from sending further data. The gate array reads the data latched periodically with generating an interrupt. -

Page 54: Eeprom Control Circuit

Operating Principles LQ-300 Service Manual 2.3.11 EEPROM Control Circuit Figure 2-23 shows the EEPROM control circuit block diagram. The EEPROM (IC6) contains such information as the top-of-form position. The EEPROM is non-volatile memory, so information is not lost if the printer is powered off. Since the EEPROM is a serial I/O-type device, the CPU converts 8-bit data into serial data. -

Page 55: Color Ribbon Sensorcircuit

Operating PrinciMes LQ-300 Service Manual 2.3.13 Color Ribbon Sensor Circuit The printer’s color ribbon circuitry is shown in the figure below. The CPU receives signals (HIGH or LOW) from the mechanical switch. The signal is HIGH (ON) when a color ribbon is installed and is LOW (OFF) otherwise. - Page 56 CHAPTER 3 Disassembly and Assembly Table of Contents 3.1 OVERVIEW 3.1.1 Disassembly Precautions ........3-1 3.1.2 Tools .

-

Page 57: Overview

CHAPTER 3 Disassembly and Assembly Table of Contents 3.1 OVERVIEW 3.1.1 Disassembly Precautions ........3-1 3.1.2 ToOIS . -

Page 58: Disassembly Precautions

Disassembly and Assembly LQ-300 Service Manual OVERVIEW This section describes various points to note when disassembling and assembling the printer. 3.1.1 Disassembly Precautions Follow the precautions below when disassembling the printer. disassembling, assembling, or adjusting the printer, disconnect the power supply... -

Page 59: Service Checksafterrepair

LQ-300 Service Manual Disassembly and Assembly 3.1.3 Service Checks After Repair Before returning the printer after service, use the checklist in Table 3-3, which provides a record to make servicing and shipping more effiaent. Table 3-3. Inspection Check list for Repaired Printer... -

Page 60: Specifications Forscrews

Disassembly and Assembly LQ-300 Service Manual 3.1.4 Specifications for Screws Table 3-4 lists the abbreviations used in the following sections for small parts, such as screws washers. Table 3-4. Screw Abbreviations Abbreviation Part Name Cross-recessed pan head screw Cross-recessed pan head B-tight screw... -

Page 61: Disassembly And Assembly

LQ+?O Service Manual Disassembly and Assembly DISASSEMBLY AND ASSEMBLY ,’ This section describes the procedures for disassembling and assembling the main components of the printer. When the procedure for installing a component is simply the reverse of the procedure for removing the component, no description of the installation is given. Any points of special concern follow the description of the procedure. -

Page 62: Removing The Printhead

Disassembly and Assembly LQ-300 Service Manual 3.2.1 Removing the Printhead Remove the printer cover assembly, edge guide assembly, ribbon cartridge, tractor assembly, platen knob, and color upgrade kit. 2. Remove the CPB (M3 x 14) screw attaching the printhead to the carnage assembly. -

Page 63: Removing The Upper Housing Assembly

LQ-300 Service Manual Disassembly and Assembly 3.2.2 Removing the Upper Housing Assembly 1. Remove the printer cover assembly, edge guide assembly, ribbon cartridge, tractor assembly, platen knob, and optional color upgrade kit. 2. Remove 4 CPB (M4 x 12) screws attaching the upper housing assembly to the lower housing assembly. -

Page 64: Removing The Main And Psb/Pse Board Assemblies

Disassembly and Assembly LC?-300 Service Manual 3.2.3 Removing the MAIN and PSB/PSE Board Assemblies Remove the printer cover assembly, edge guide assembly, ribbon cartridge, tractor assembly, platen knob, and optional color upgrade kit. Remove the upper housing assembly (see Section 3.2.2). Disconnect 4 flexible flat cables (FFCS) and 7 connectors from the MAIN and PSB/PSE board assemblies. -

Page 65: Removing The Main Board Assembly

Disassembly and Assembly LQ-300 Service Manual MAIN Board Assembly Removing the 3.2.3.1 1. Remove the PSB/PSEboard assembly FFC fromconnector CN20fthe MAIN board assembly. 2. Remove the CBC (M3x8)screwand the3CBUSCAC (M3 x8). 3. Remove the MAIN board assembly. 3.2.3.2 Removing the PSB/PSE Board Assembly Remove the FFC for the PSB/F’SE board assembly from connector CN2 on the MAIN board... -

Page 66: Removing The Printer Mechanism

Disassembly and Assembly LQ-300 Service Manual Removing the Printer Mechanism 3.2.4 Remove tie Pfiter cover assemblies, edge guide assemblies, ribbon cartridge, tractor assemblies, platen knob, and optional color upgrade kit. Remove the upper housing assembly (see Section 3.2.2). Remove the connectors and FFCS from the MAIN board assembly. -

Page 67: Removing The Pf Motor

LQ-300 Service Manual Disassembly and Assembly Removing 3.2.4.1 the PF Motor 1. Remove the printer mechanism (see Section 3.2.4). 2. Remove the platen grounding spring thatsecures theplatenshaft (see Section 3.2.4.3). 3. Remove the CBB (M3 x8) screw attaching the PFmotorto the nghtframe. -

Page 68: Removing The Cr Motor

Disassembly and Assembly LQ-300 Service Manual Removing the CR Motor 3.2.4.2 Remove the printer mechanism (see Section 3.2.4). 2. Remove the extension spring from the hook on the CR motor and the hook on the base frame. 3. Remove the timing belt from the pulley drive. -

Page 69: Removing The Platen

LQ+OO Service Manual Disassembly and Assembly 3.2.4.3 Removing the Platen 1. Remove the printer mechanism (see Section 3.2.4). 2. Remove the platen gmundingspring that secures the platen shaft. 3. Remove the 25 mm gear from the right frame. 4. Disengage the teeth of the 211 mm bushings and rotate them. 5. -

Page 70: Removing The Pe Sensor

Disassembly and Assembly LQ-300 Service Manual Sensor Removing the PE 3.2.4.4 Remove the printer mechanism (see Section 3.2.4). Remove the platen (see Section3.2.4.3)- 3. Release the friction shaft of theupperpaper Wide from the clips on the right and left frame. -

Page 71: Removing The Hp Sensor

Disassembly and Assembly LG?-300 Service Manual Removing the HP Sensor 3.2.4.5 1. Remove theprinter mechanism (see Section 3.2.4). 2. Release the 2 clips attaching the HP sensor and remove it. The clips can be accessed though 2 holes in the base frame. To release the clips, push each with a pair of tweezers. Base Figure 3-14. -

Page 72: Removing The Carriage Assembly

Disassembly and Assembly LQ-300 Service Manual 3.2.4.7 Removing the Carriage Assembly Remove the printer mechanism (see Section 3.2.4). 2. Remove the belt tension spring from the hook on the CR motor (see Section 3.2.4.2), and remove the carriage assembly timing belt from the drive pulley. -

Page 73: Removing The Ribbon Drive Gear Assembly

LQ-300 Service Manual Disassembly and AssemblY Removing the Ribbon Drive Gear Assembly 3.2.4.8 1. Remove the printer mechanism (see Section 3.2.4). 2. Release the 3 hooks attaching the ribbon drive (RD) cover to the left frame. 3. Remove the RDcover. -

Page 74: Removing The

Disassembly and Assembly LQ-300 Service Manual 3.2.4.9 Removing the PG Sensor Remove the printer mechanism (see Section 3.2.4). 2. Release the 2 clips attaching the PG sensor and remove it. The clips can be accessed through 2 holes in the left frame; to release the clips, push each with a pair of tweezers. -

Page 75: Removing The Interface Board Assembly

LWOO Service Manual Disassembly and Assembly 3.2.5 Removing the Interface Board Assembly 1. Remove theprinter mechanism (see Section 3.2.4). 2. Remove the grounding plate connecting the interface shield plate and theshieldplate. 3. Remove the CBB (M3 x 8) screw and the CBB (M3 x 10) screw attaching the bottom cover to the lower housing assembly. -

Page 76: Removing The Driven Roller Assembly

Disassembly and Assembly LQ-300 Service Manual 3.2.6 Removing the Driven Roller Assembly Remove the printer cover. 2. Remove the CFP (M2.6 x 8) screw attaching the driven roller assembly. 3. Remove the driven roller assembly. CFP(M2.6X8) Driven Roller 73g Spring Ta/A “h... -

Page 77: Disassembling And Assembling The Color Upgrade Kit

Disassembly and Assembly LQ-300 Service Manual 3.2.7 Disassembling and Assembling the Color Upgrade Kit 3.2.7.1 Removing the Ribbon Motor Assembly 1. Remove the CBB (h43 x 8) screws attaching the ribbon motor assembly to the CS cover. 2. Release the 2 clips attached to the CS cover. - Page 78 CHAPTER 4 Adjustments Table of Contents 4.1 ADJUSTING THE PRINTER MECHANISM 4.1.1 Platen Gap Adjustment ........4-1 SEITINGS, 4.2 DEFAULTS, MACHINE INFORMATION BIDIRECTIONAL ADJUSTMENT...

-

Page 79: Adjusting The Printer Mechanism

Adjustments LQ-300 Service Manual 4.1 ADJUSTING THE PRINTER MECHANISM This section describes the adjustments you may need to make to the printer mechanism. 4.1.1 Platen Gap Adjustment you have rotated or reassembled the CR guide shaft assembly or the parallelism adjustment bushing, or if printing is abnormal, you must adjust the platen and the printhead. -

Page 80: Defaults, Machine Information Seitings, And Bidirectional Adjustment

LQ-300 Service Manual Adjustments DEFAULTS, MACHINE INFORMATION SEITINGS, AND BIDIRECTIONAL ADJUSTMENT 4.2.1 Defaults and Machine Information Settings Perform the procedure below when the main board assembly is replaced. Connect the printer to a PC. Turn the printer on. Load paper into the printer by pressing the LF/FF button. You can use either cut sheet or continuous paper. - Page 81 Adjustments LQ-300 Service Manual Press Y, then Enter. The default setting table appears on the display: SW& Valid Add Function English language Model ID PC-437 Character table 11 inch Page length (Tractor) Skip-over-perforation Auto tear-off Uni-D Graphic Print Direction ESC/P2...

- Page 82 LQ-300 Service Manual Adjustments Bidirectional Adjustment 4.2.2 This section describes the adjustment procedure necessary when the LQ-300 printer is reassembled or when parts are reinstalled or replaced. This procedure is also necessary if the main board assembly has been replaced.

- Page 83 Adjustments LQ-300 Service Manual After printing is complete, the following message appears on the display: From the 5 rows of draft patterns, find the row in which the vertical lines in the H are best aligned, then enter the value assigned to that row. The following figure is an example of the Bi-D printout.

- Page 84 Chapter 5 Troubleshooting Table of Contents 5.1 OVERVIEW UNIT LEVEL TROUBLESHOOTING 5-11 5.3 REPAIRING THE MAIN BOARD ASSEMBLY 5-13 5.4 REPAIRING THE PRINTER MECHANISM Figures List of Figure 5-1. Troubleshooting Procedures ......5-1 Printhead ConnectorPin Alignment .

- Page 85 Troubleshooting LQ-300 Service Manual OVERVIEW Follow the procedures in the flowchart below to identify printer problems. S T A R T Section Page I D e s c r i p t i o n ( The Fault is Corrected ) Figure 5-1.

- Page 86 Troubleshooting LQ-300 Service Manual Pin No. Head 7 C C C 22151823 10 14 6 311 219 ~ Printhead Head Pin No. 5 1 13 921 17 C C C 2416 12 8 20 4 C: COMMON View A Figure 5-2. Printhead Connector Pin Alignment Table 5-2.

- Page 87 LQ-300 Service Manual Troubleshooting Table 5-3. Motor Coil Resistance Test Points Test Method Motor Common Test Pin (Set Meter to Ohms. Disconnect Meter Reading Connector Number Motor from Main Board and Check it Number Number with Printer Power Off.) CR Motor...

-

Page 88: Unit Level Troubleshooting

Troubleshooting LQ-300 Service Manual UNIT LEVEL TROUBLESHOOTING You may be able to identify the defective unit just from the symptom displayed. The table below provides the symptoms for a number of failures, so that you can easily identify the problem. Once the problem has been identified, refer to the flowchart listed in the right-hand column of the table bel~w to determine the cause of the problem. - Page 89 Troubleshooting LQ-300 Service Manual 1. Printer fails to operate when the power is on. Is the AC input voltage normal? 120 V is 103.5-132 V version range 230 V version range is 198-264 V ~“” ‘T Replace the fuse. VP (+35 VDC)

- Page 90 LQ-300 Sarvice Manual Troubleshooting 2. Abnormal carriage operation. Are connectors CN2 - CNIO Reinsert connectors connecting the MAIN Board Assembly correctly. and the Printer Mechanism See the troubleshooting items under Printer Mecnanism (Section 5.4). Check the sensor. motor and drivers with fault corrected7 the same time.

- Page 91 Troubleshooting LQ-300 Service Manual Printing is faulty during self-test, but carriage operation is normal. Use correct AC input voltage. No fluctuation from AC voltage 120 V version range is 103.5-132 V range is permitted. 0 V version range is 198-264...

- Page 92 LQ-3# Sarvice Manual Troubleshooting 4. Abnormal paper feed. START I YES when turned manual smoothly with the power off? Check the resistance of See the troubleshooting the PF motor and check items for the printer mechanism ((Section 5.4). the PF motor drivers. If anything is bad, replace.

- Page 93 Troubleshooting LQ-300 Service Manual Abnormal control panel operation. START button! ----- click ‘‘- < Replace the upper Check the switches using a multimeter. If bad, replace the upper housing assemb Iv. IReplace the MAIN Board I Refer to the other fault corrected? troubleshooting items.

- Page 94 LQ~OO Service Manual Troubleshooting 6. Data sent by the host computer is printed incorrectly. START Print the self-test. Refer to the other troubleshooting items. Check the default settings. ‘F fault corrected? I YES I Replace the MAIN I Increase the the setting of the paper-thickness lever.

-

Page 95: Repairing The Main Board Assembly

LQ-300 Service Manual Troubleshooting REPAIRING THE MAIN BOARD ASSEMBLY This section provides instructions for repairing a defective main board assembly. It describes Checkpoints refer to proper waveforms, various symptoms, likely causes, and checkpoints. resistance values, and other values to be checked when evaluating the operation of any potentially faulty component. - Page 96 LQ-3OO Troubleshooting Service Manual Table 5-7. Repairing Problems in the Main Board Assembly (Continued) 5-12 Rev.A...

-

Page 97: Repairing The Printer Mechanism

Troubleshooting LQ-300 Service Manual 5.4 REPAIRING THE PRINTER MECHANISM For detailed procedures for replacing or adjusting parts, refer to Chapter 3, Disassembly and Assembly, and Chapter 4, Adjustments. If a problem or symptom recurs folIowing an attempted repair, refer to Table 5-8 and try to find other potential causes. - Page 98 Troubleshooting LQ-300 Service Manual Table 5-8. Repairing the Printer Mechanism (Continued) Problem Symptom Checkpoint Soiution Cause Self-test A particular The printhead Measure the pnnthead ooil Replaoe the printing is dot is missing. is defective. printhead (and resistance. it should be abnormal.

- Page 99 CHAPTER 6 Maintenance Table of Contents 6.1 PREVENTIVE MAINTENANCE 6.2 APPLYING LUBRICATION List of Figures Figure 6-1. LQ-300 Lubrication Points....... . 6-2 List of Tables .

-

Page 100: Preventive Maintenance

6.2 APPLYING LUBRICATION EPSON recommends that the printer be lubricated at the points dlustrated in Figure 6-1. Table 6-2 lists each point along with its recommended lubricant. The recommended lubricants are EPSON G-20, G26 and O-2, all of which have been tested extensively and found to comply with the needs of this printer. - Page 101 LQ-300 Service Manual Maintenance Figure 6-1. LQ-300 Lubrication Points Rev.A...

- Page 102 Appendix Table of Contents A.1 CONNECTOR SUMMARY A.2 CIRCUIT DIAGRAMS A.3 CIRCUIT BOARD COMPONENT LAYOUTS A - n A.4 EXPLODED DIAGRAMS A.5 CASE OUTLINE DRAWING A-17 List of Figures Figure A-1. Cable Connections........A-1 Figure A-2.

-

Page 103: Printer Mechanism

Appendix LQ-300 Service Manual A.1 CONNECTOR SUMMARY Figure A-1 illustrates how the primary components are comected. Table A-1 SUrnmariZeS the functions and sizes of the connectors. Printer Mechanism PG Sensor — — Release Lever Position Sensor HP Sensor CR Motor Assembly I ‘d”’... - Page 104 LQ-300 Service Manual Appendix Table Connector Summary A-1. Function Pins Board I Connector MAIN Parallel, serial interface Board CR motor Assembly PF motor I-+5 PSB/PSE board assembly Printhead Printhead PE sensor t--++ HP sensor Release lever Dosition sensor CN1O PG sensor...

- Page 105 Appendix LQ-300 Service Manual Table A-5. Connector Pin Assignments - CN5 Function Signai Name Head data 3 HD 3 Head data 11 HD 11 Head data 2 HD 2 Head HD 19 data 19 HD 7 Head data 7 —...

- Page 106 LQ-300 Service Manual Appendix Table A-9. Connector Pin Assignments - CN9 Function Signal Name RELSW Release lever position sensor signal — Signal ground Table A-10. Connector Pin Assignments - CN1O Signal Name Function Platen gap sensor signal Gap-Adj Signal ground —...

- Page 107 Appendik LQ-300 Service Manual iiiim .m ? Figure A-3. C130 PSB Circuit Diagram Rev.A...

- Page 108 Service Manual LQ-300 Appendix . , , . & e ..; ’ ,./ 1> l-’ — G+– Figure A-4. C130 PSE Circuit Diagram Rev.A...

- Page 109 Appandix LWOO Sewice Manual A.3 COMPONENT LAYOUTS 4%4% l&.Y L&” %----n &lml @mlm Figure A-5. C143 MAIN Component Layout Rev.A...

- Page 110 , . . Figure A-6. C130 PSB/PSE Component Layout...

- Page 111 Lq-3OO Service Appendix Manual A.4. EXPLODED DIAGRAMS Figure A-7. LQ-300 Exploded Diagram (1) A-1 1 Rev.A...

- Page 112 LC?-MMS&vbeMantd Appendix “v / \, Q&ix=@-iyii?!!! Figure A-8. LQ-300 Exploded Diagram (2) Rev.A A-12...

- Page 113 Appendix L WOO Service Manual ‘ o / ’ Figure A-9. Color Upgrade Kit Exploded Diagram A-13 Rev.A...

- Page 114 Table A-12. Pti Ncx Reference Table Ref. PPL Name Desoriptkm PPL Name p;” 100 Housing Lower housing bsulator Insufator Assv..Lower assembtv 102 Insulator Insulator 103 Shield Plate Shield pfate 104 Cover Assy.,Printer Printer oover 105 Roller,Driven Drhmn @er assembly 107 Compression 106 Hoider,Rofkr, Driven roller holder 739~...

- Page 115 Appendix LQ-300 Service Manual Table A-12. Part No. Reference Table (Continued) Ref. Ref. Description Name Description PPL Name Base frame 516 Paper Guide Paper guide 517 Frame,Base support support 5.1, 16.2 mm 13.2 mm spur gear 519 Combination 518 Spur Gear,13.2 combination gear Gear,5.1,1 6.2...

- Page 116 Appendix L- Seruk8 MMud Table A-12. Part No. Reference Table (Continued) Ref. PPL Name Description gt” PPL Name 578 P.w.,8.4xo.lx15, PW 8.4x0.lx15 579 Plain Washer Plainwasher SANA Grounding I/Vim, Left platen Mounting Plate CR motor mounthg Platen,Left grounding wife Assy.,CR Motor plate assembly C.P.

- Page 117 Appendix LWOO Service Manual A.5 CASE OUTLINE DRAWING — —. 275mm 132mm Figure A-10. LQ-300 Case Outline Drawing A-17 Rev.A...

- Page 118 EPSON OVERSEAS MARKETING LOCATIONS EPSON AMERICA, INC. EPSON DEUTSCHLAND GmbH 20770 Madrona Avenue, ZUpicher Stra13e 6,4000 Diksseldorf 11 P.O. 2842 F.R. Germany Torrance, CA 90509-2842 Phone: 0211-56030 Phone: (800) 922-8911 Fax: 0211-504-7787 Fax: (310) 782-5220 EPSON UK LTD. EPSON FRANCE S.A.